Last week I was visited by my friend Bill Binko who helped me build a new version of my ultimate remote. I will post a new blog post about that remote soon. While he was here we shot some video that gives an overview of various assistive technology that I use on a daily basis including a demonstration of the newest version of the remote. Here is the YouTube video.

Category Archives: Assistive Technology

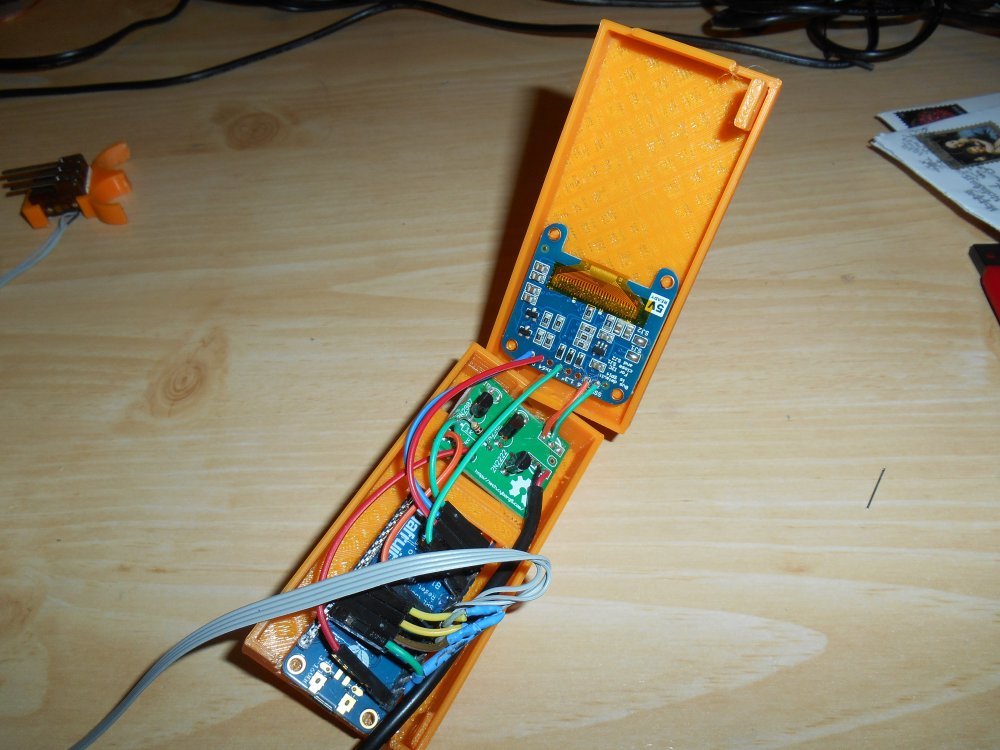

Sometimes Perfect Wiring is Wrong

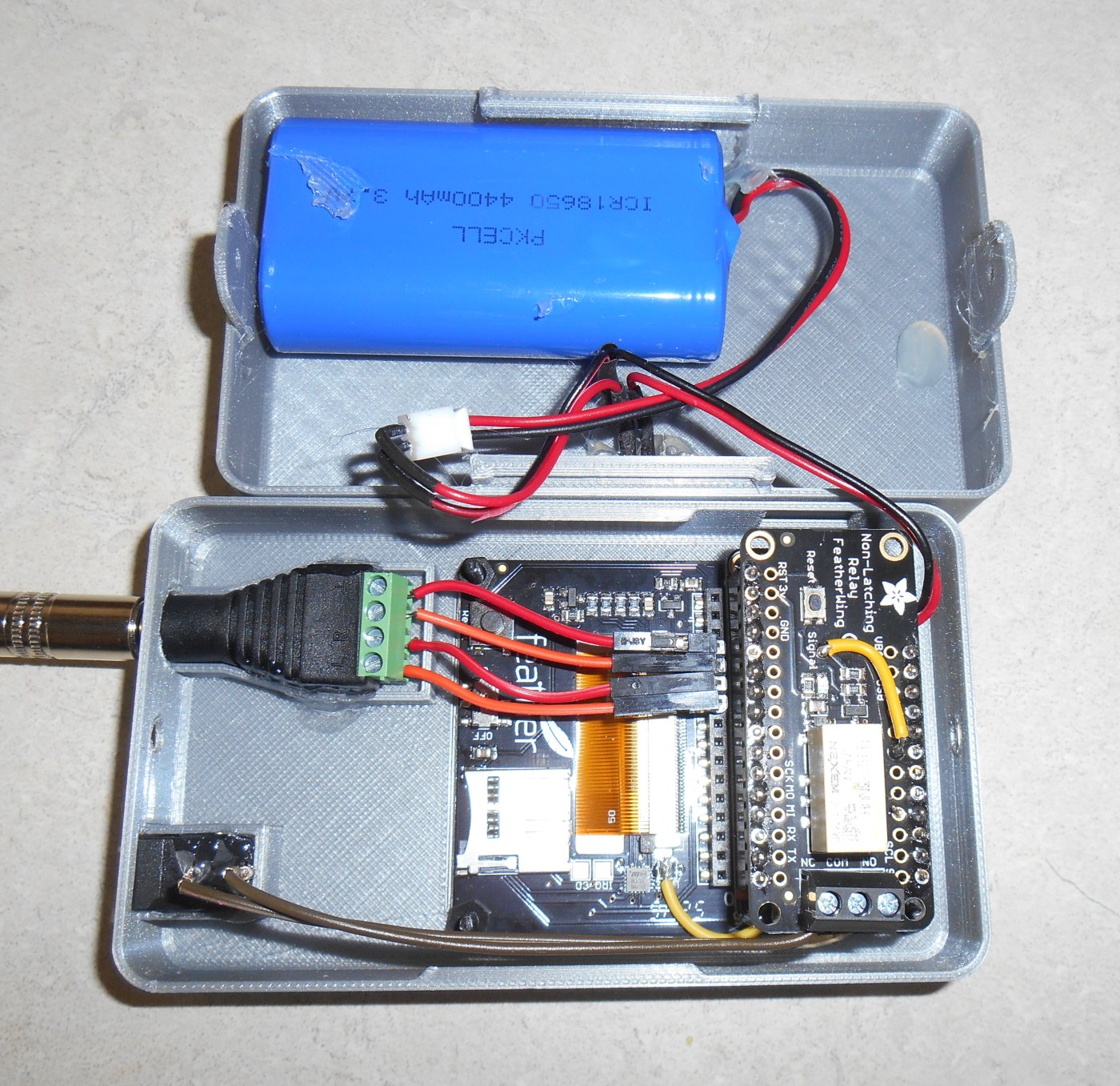

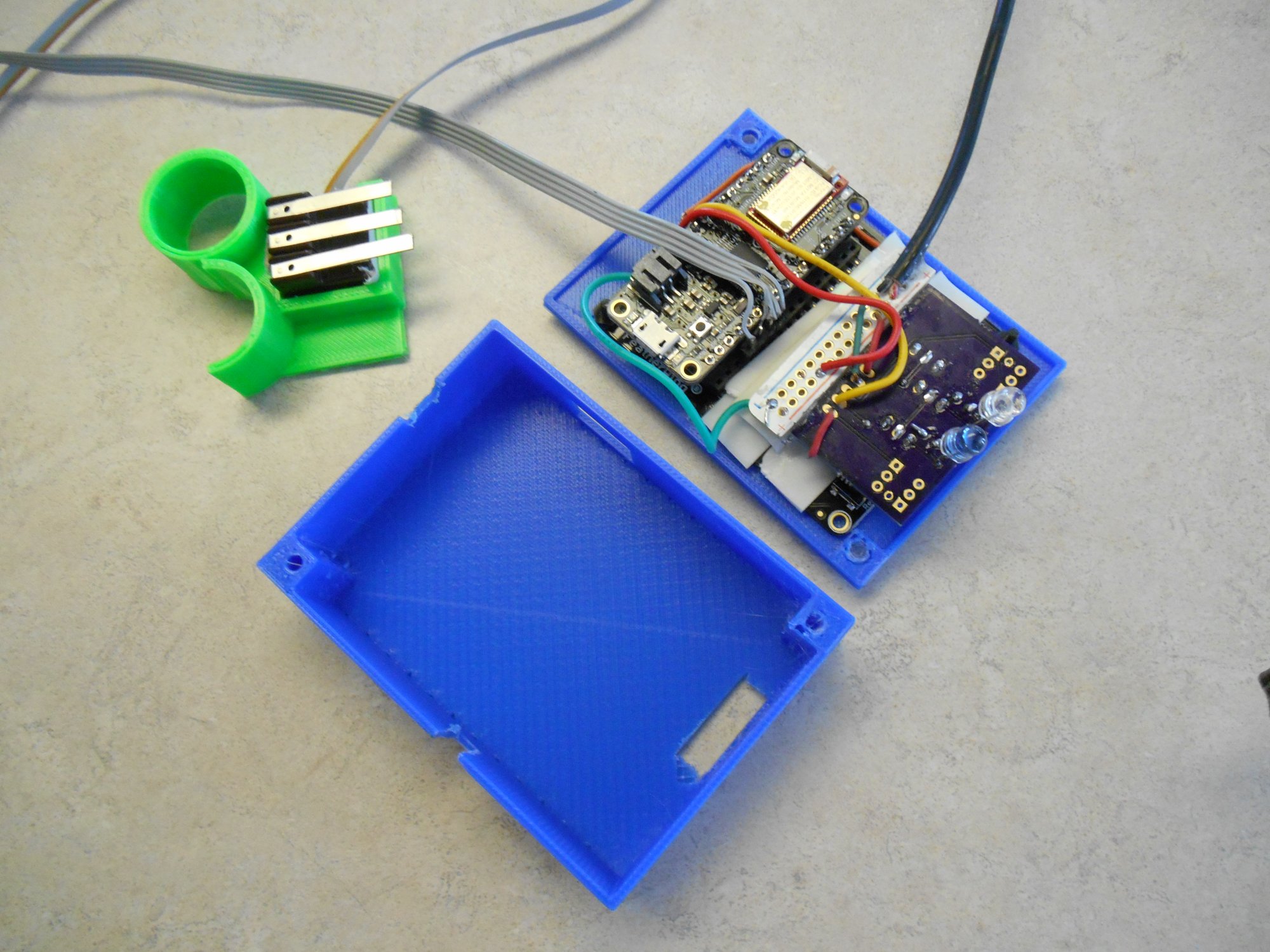

The image above is the interior of a specialized version of my Ultimate Remote. It does mouse and keyboard control for my laptop via USB plug-in. It also will do Bluetooth switch control on my iPad or iPhone. Like my other specialized remotes, there is an LCD screen and an Adafruit Feather M0 BLE. But what really makes this one special is that it includes a relay that can be connected by cable to a nurse call system at St. Vincent Hospital. The cable has a standard quarter-inch mono headphone plug on the other end that plugs into the wall in the hospital room. The white rectangular box on the right side of the image is a relay that can be triggered to call the nurse. By using a mechanical relay, it isolates my electronics completely from the hospital’s nurse call system. Although the hospital has allowed me to plug a cable with a simple pushbutton on the other end into their system, I don’t know if they will allow me to plug in this more advanced system. But I built it anyway just in case. The problem is, I can only handle one set of buttons at a time. Either use my Bluetooth and USB mouse and keyboard system or I can use the nurse call system. This box would allow me to do both at the same time.

The St. Vincent Hospital system is wired so that it is normally closed. When you push the call button, the circuit opens and it triggers an alarm to call the nurse. The system used to be normally open years ago. But someone realized that if you accidentally pull the cable out of the wall there’s no way to know that it is disconnected. With a normally closed system if the cable gets pulled out it would trigger the alarm. This system is not used for everyday patients. Most patients use a nurse call button that is wired into the bed. The jack in the wall is only used for specialized call buttons. But because their system is normally closed, you can’t just have an empty jack. Otherwise the alarm would constantly ring. They have a small “keeper” plug that sticks in the hole when the system is not in use.

Here’s the problem… I recently toured a skilled nursing facility on the south side of town in Greenwood. There’s a possibility that if my sister could no longer be my caregiver, I might have to go there to live at least on a temporary basis until I could find some sort of group home residential setting. I was thrilled to see that there nurse call system use the same quarter inch mono headphone jack to plug into the wall. It looked identical to the jack hole at St. Vincent with one exception.

There was no keeper plug stuck in the hole. That means that the Greenwood facility is wired “normally open”. When you push the button, it closes the circuit. My standalone cable with a simple pushbutton that I’ve been using at St. Vincent for years as well as my newfangled box are both wired as normally closed. So I built another cable with another simple switch and wired it normally open. Now I have one of each. One for St. Vincent and one for Greenwood Healthcare. But of course I didn’t want to build an entire new box for the advanced version to use in Greenwood should I need to go there.

Take a closer look at the terminals connected to the relay in my box. There are three screw terminals just below the relay into which we connected 2 brown wires that run to a jack on the left side of the box. Take a moment to appreciate what a wonderful job my dad did when wiring up this box. Those two brown wires have been perfectly trimmed to the proper length. One of them goes to the left terminal which if you look closely in this image is labeled “NC” standing for “normally closed” and the center terminal is the common terminal labeled “COM”. Unused on the right is a terminal labeled “NO” meaning “normally open”. All I have to do to convert the system is to move the wire from the “NC” terminal to the “NO” terminal. But as you can see… Dad’s perfect wiring job means that the wire is too short. We were both so proud of how clean the interior of this box turned out. Now I’m going to have to get someone to replace the wire with one that is about a half-inch longer.

Sometimes perfect wiring is wrong.

Another example of how the Assistive Technology procurement system is broken

There used to be a humorous TV ad for the Yellow Pages. For those of you too young to remember, Yellow Pages was a printed telephone directory full of advertisements for various businesses. You had to use these before there was Internet or Google. In the ad, a salesman was trying to sell a Yellow Pages advertisement to a business called “Don’s Rug”. It was a business run by a guy named Don who had a rug for sale. Singular. Just one rug. It wasn’t “Don’s Rugs”. He didn’t want to advertise because then someone might call him and want to buy his rug. Then he would be out of business. Then the voiceover said “Unless you don’t want to have any customers like Don, you should be advertising in the Yellow Pages.”

The ridiculousness of the example is what proved their point. If you want to sell your product you need to make it easy for people to find you and to purchase the product. Otherwise why did you even bother going into business?

Apparently some people in the assistive technology business must be a lot like Don’s Rug. For some reason they aren’t very anxious to get people’s business. Let me explain what it is I’m trying to purchase.

I’ve always been disappointed that Windows 10 doesn’t have switch control features to the extent that Mac OS or iOS devices have. I’ve never been a big fan of Apple. I only reluctantly purchased an iPhone because I needed the switch control features. Even though Android has made progress in that area, it still isn’t anywhere near what’s available in iOS. With the exception of the on-screen keyboard it Windows 10 that only supports single switch not dual switch scanning, there just isn’t anything in Windows 10. It’s nice that the latest update has built-in support for eye tracking but I don’t want to do eye tracking.

So someone recommended I check out some software called Grid 3 sold by a company called Think Smart Box. It’s a general AAC communication software the duplicates some functions you would see in speech generating application such as Cough Drop. But all I really want is to use it for its ability to control a Windows PC. Cough Drop can’t do that. It’s just four generating speech. So I go to the website for Grid 3 and they don’t have any prices. There is a form you can fill out to get a quote. Right then I knew it wasn’t a good sign. But I thought I would humor them and asked for a quote.

Two days later I get a nice email explaining that they don’t do direct sales. They only sell through dealers. I appreciate the fact that many users need a lot of support. They want to bundle switches, other input devices, need training setting up communication screens etc. etc. But I just want to control my Windows PC and I’m perfectly capable of installing it all myself. Not only do they only sell through a dealer network, they don’t have a dealer in the state of Indiana. They referred me to a dealer in Wisconsin. What? They don’t even have someone in Chicago, Cincinnati, St. Louis, Cleveland. Basically I told them thanks but no thanks. It’s bad enough that they won’t tell me what the software costs. Add to that they don’t want to sell it to me directly. I told them they lost a customer with their stupid policies.

I will leave it as an exercise for the reader to speculate why they would have such a policy. Perhaps they really are like Don’s Rug and don’t want to sell their product. Or perhaps they’re more concerned about lining the pockets of their dealer network then they are providing their product to the end-user. Just a couple of possible explanations.

Meanwhile I’m 3D printing a bracket that will hold my iPad Mini 2 on top of my TV monitor so I can watch TV and/or use my Windows laptop as a computer and then use the iPad for communicating while I’m on my ventilator. Just another way that the whole AT system is broken.

Epilog: I did eventually get another email reply from the company. The tone was pleasant and apologetic. They do offer direct sales in the UK but not the US. The software is $735. While that’s pretty steep, given all of the capabilities it’s not completely unreasonable. But I really only need it for a small portion of its capability and I’m not really sure it’s worth it. I will have to consider it as an option. The email explained that most of their purchases are through Medicare, Medicaid or other insurance providers. While it offers some explanation, it just furthers my contention that the system is badly broken.

Switch Controled Assistive Technology Mouse Using Feather 32u4 and OLED Display

In the ATMakers.org Facebook page we’ve been discussing the development of an assistive technology device we are preliminarily calling APHID. It’s my belief that at least one version of our APHID device will need some sort of display. Here is a proof of concept of the device using a feather 32u4, OLED display and three switches. It does every kind of mouse control that you could imagine as well as the limited keyboard commands. This device is connected through USB but we could also make a Bluetooth version.

How I Sleep Better Thanks to My New IPad

I’ve already chronicled the story of my month-long stay in the hospital last December which resulted in getting a trach and being on a ventilator. The worst part of the experience is that I am not be able to talk while on the vent. Fortunately I only need to be on the ventilator now at night to help me sleep. However the communications issues are still a problem. It’s common for me to need to call my dad in the middle of the night to rollover or to suction out the trach.

My main means of communication with my dad while on the vent consists of messages I type on my laptop. My laptop sits on my dresser next to me on top of my cable box. A long HDMI cable runs from the laptop around the back of my bed and up to the TV hanging on the wall over my bed as can be seen in this image.

You can click on any of these images for larger versions. There is also an HDMI cable from the TV to the cable box. By switching inputs on the TV, I can either watch cable TV or use the laptop. Normally computer control on my desktop or laptop is via dictation software Dragon NaturallySpeaking but of course if I’m on the ventilator I cannot talk to use the computer. However I have an infrared remote control that not only controls the cable box and TV but it provides mouse control and some keyboard controls for the laptop (mostly arrow keys). The IR control is in the black box sitting on top of the TV.

When I get on the ventilator at about 11 PM each night, I call up a notepad window on the laptop and use the Windows on-screen keyboard. I have it set up in scanning mode and use a single switch on my IR remote to type on the keyboard. I have a couple of files of text with standard messages but then I can type anything I want as well.

The system has worked very well ever since I got out of the hospital late last December but I’m finding it’s uncomfortable to lie on my back all night long. Typically I wake up somewhere between 5 AM and 8 AM and need my vent suctioned. At that point I’m more comfortable if I rollover on my right side.

The problem with lying on my side is that I can’t see the TV monitor to see what I’m typing on the laptop. Also there is a small black box on top of the TV that is my IR remote control. It has a 2×16 character LCD display that I need to see in order to operate the IR remote. I cannot see it lying on my side either.

That meant that if I needed to communicate with my dad while on my side we had to play 20 questions. I can signal yes or no with my facial expressions. If that didn’t work he had to take me off the ventilator and insert my talking valve. I needed some sort of device that both he and I could see while lying on my side.

When I was in the hospital I used Bluetooth switch control to type messages on my iPhone to communicate with doctors, nurses, and family. However the iPhone screen is pretty small so I decided I would buy an iPad. I settled on an iPad mini 2. As you can see in the image it sits on top of my laptop and cable box. I could’ve opened the lid on the laptop but it was sitting at an angle that would make it difficult for me to see. The iPad is a better choice. Also if I’m ever in the hospital again I will use it instead of the iPhone because it has a bigger screen.

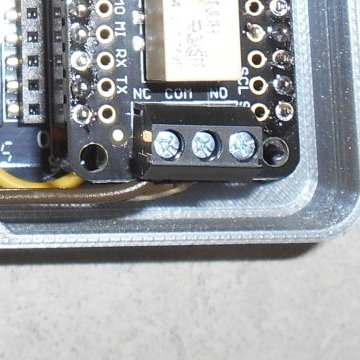

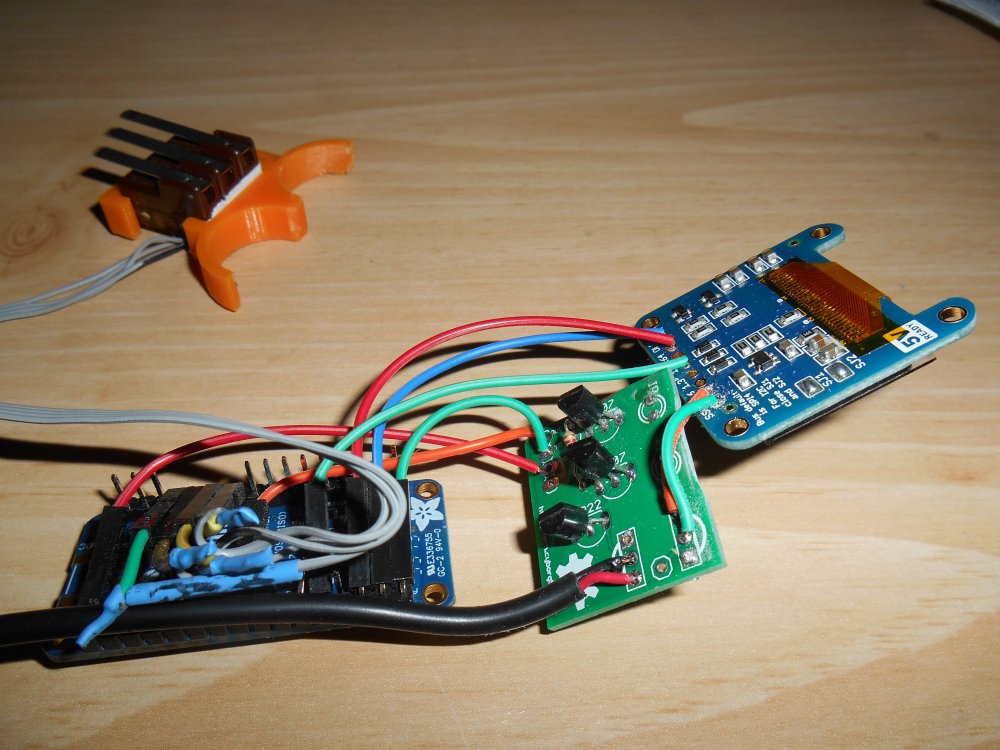

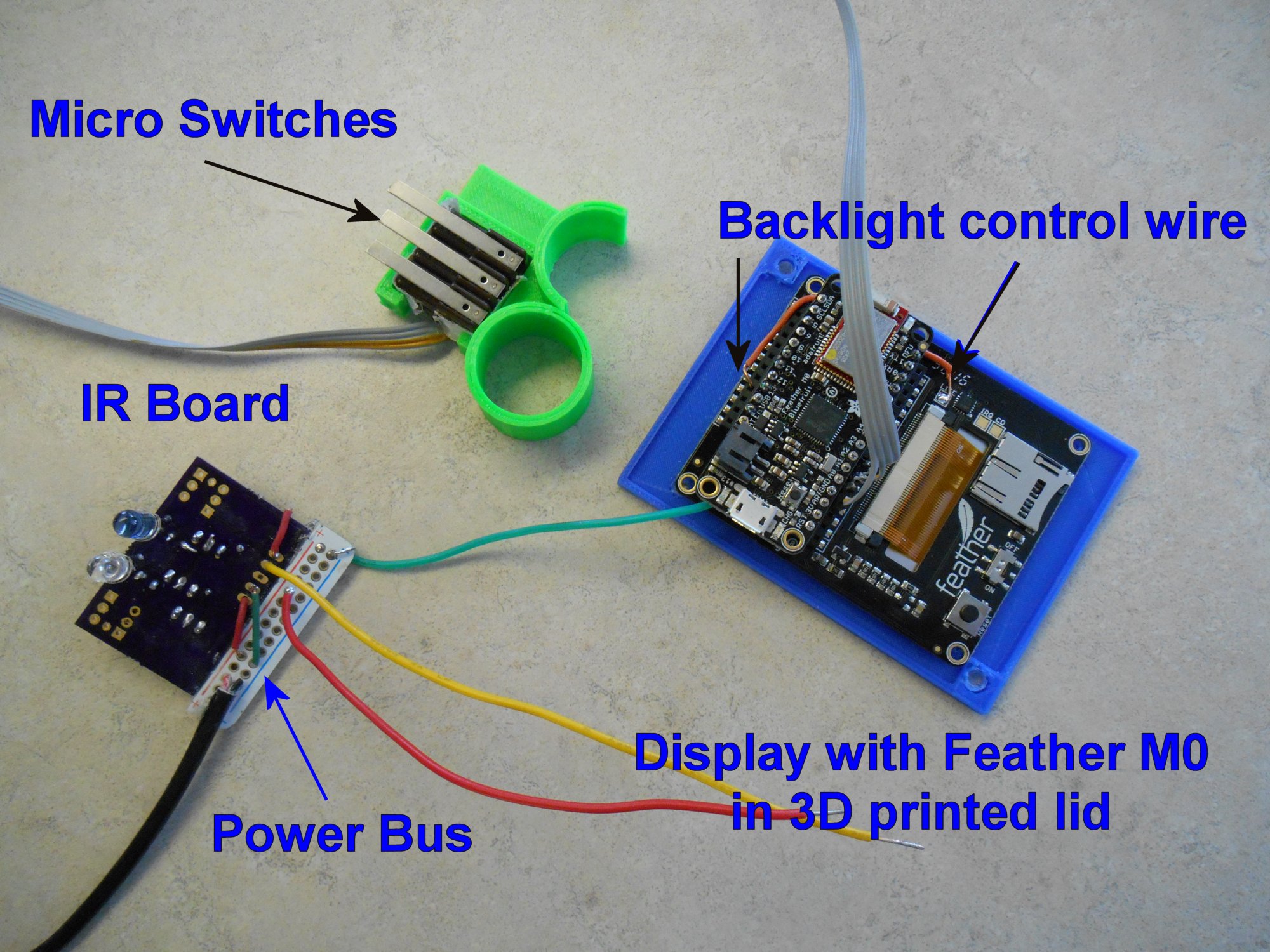

My IR remote sits on top of the TV as shown in the first image above. I control through a control box that sits on the dresser next to the cable box. The two are connected using an X-Bee radio. In addition to sending RF signals to the IR remote, it also sends RF signals to a similar device in my dad’s bedroom so that I can push a certain set of buttons and it sets off the alarm to wake him up to tell him I need something. This image shows the interior of that control box on the dresser. It consists of an Arduino Micro, X-Bee radio, Adafruit Power Boost 500C and a Lipo battery. The battery is a backup in case of a power failure.

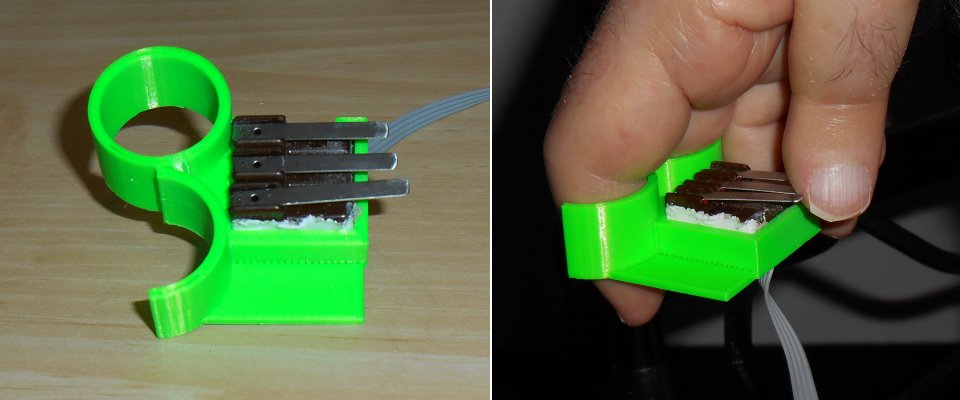

Connected to that box are three micro switches mounted in a 3D printed plastic ring that helps me hold the buttons in my hand.

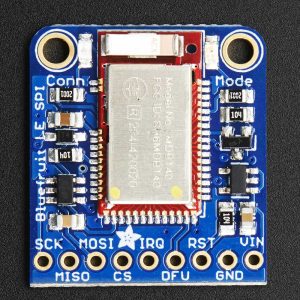

My friend Yahnatan refers to it as my Dr. Strange Sling Ring. It really made me mad when he called it that. I’m not offended. I’m mad that I didn’t think of it first! In order to control the iPad I would need to add Bluetooth of some kind to the X-Bee/Arduino device. I decided to use the Adafruit BLE SPI Friend.

If I was designing the system from scratch I would have used an Adafruit Feather 32u4 BLE with one of their RF feather wings but those didn’t exist when I first built this project. I’ve got everything already designed around a 5 V device and the X-Bee RF system. I also didn’t plan ahead thinking that I would someday need to attach an SPI device like the BLE Friend. Unfortunately I had already used the dedicated SPI pins on the Arduino Micro for other purposes. Fortunately the Adafruit Bluefruit software library has an option for software SPI. It will allow me to use any set of six pins to connect the device. I was pleasantly surprised that that feature worked right out of the box.

If I was designing the system from scratch I would have used an Adafruit Feather 32u4 BLE with one of their RF feather wings but those didn’t exist when I first built this project. I’ve got everything already designed around a 5 V device and the X-Bee RF system. I also didn’t plan ahead thinking that I would someday need to attach an SPI device like the BLE Friend. Unfortunately I had already used the dedicated SPI pins on the Arduino Micro for other purposes. Fortunately the Adafruit Bluefruit software library has an option for software SPI. It will allow me to use any set of six pins to connect the device. I was pleasantly surprised that that feature worked right out of the box.

I have the software configured so that if you press all three buttons simultaneously for more than one second it toggles between IR mode and Bluetooth mode.

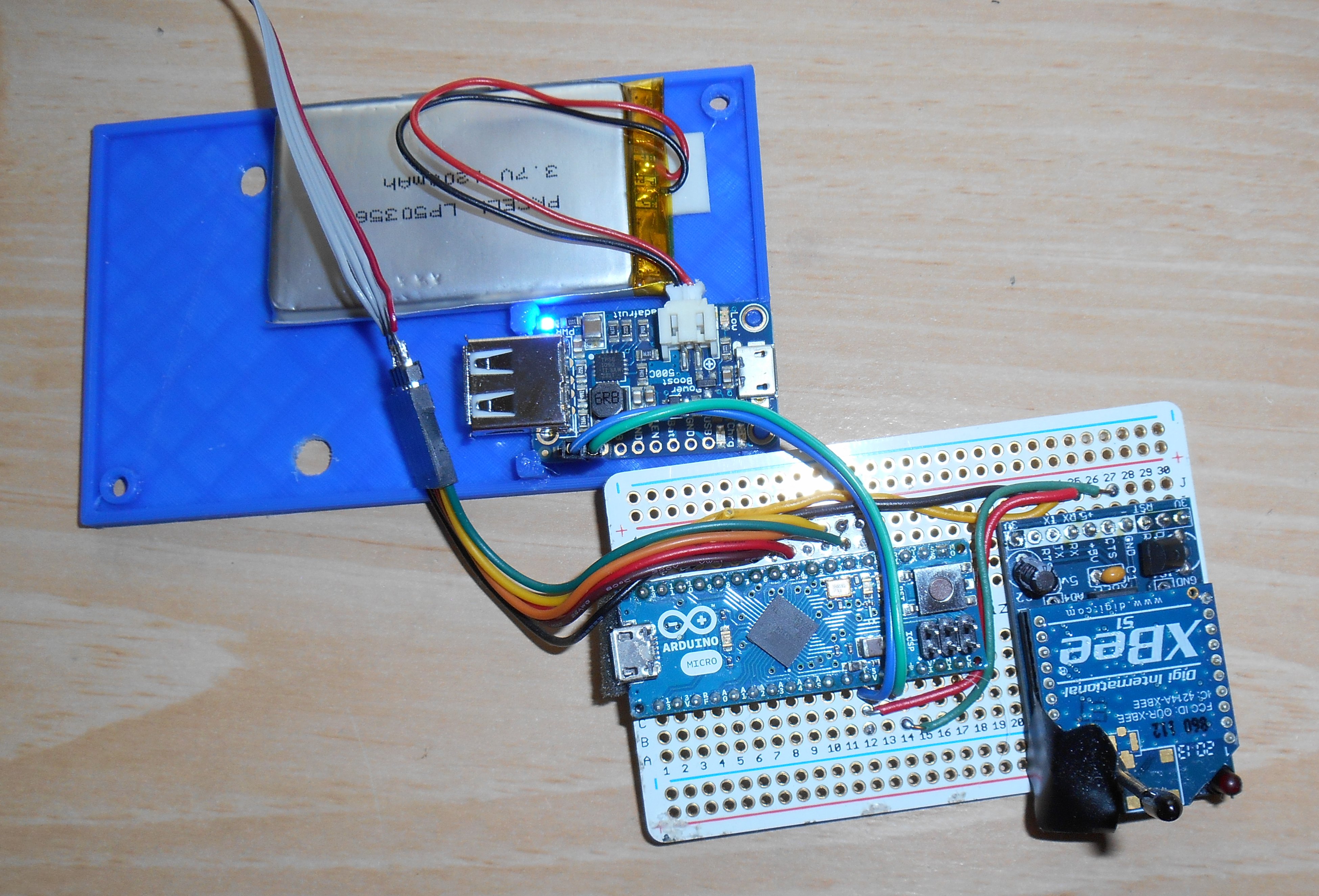

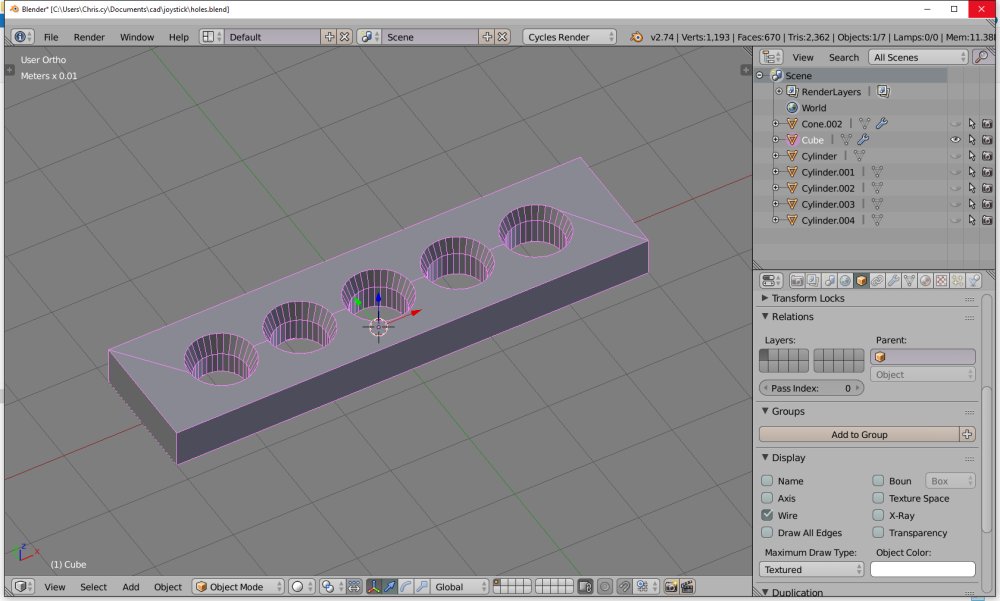

The only remaining task was to make a 3D printed stand for the iPad. I wanted something that would hold it perfectly straight up and down 90°. It had to be stabl enough that it wouldn’t knock over to easily but I wanted to be able to fold it up so it would lie flat for transport when not in use. Should I ever end up in the hospital again I would be using this iPad rather than the iPhone to communicate with doctors and nurses.

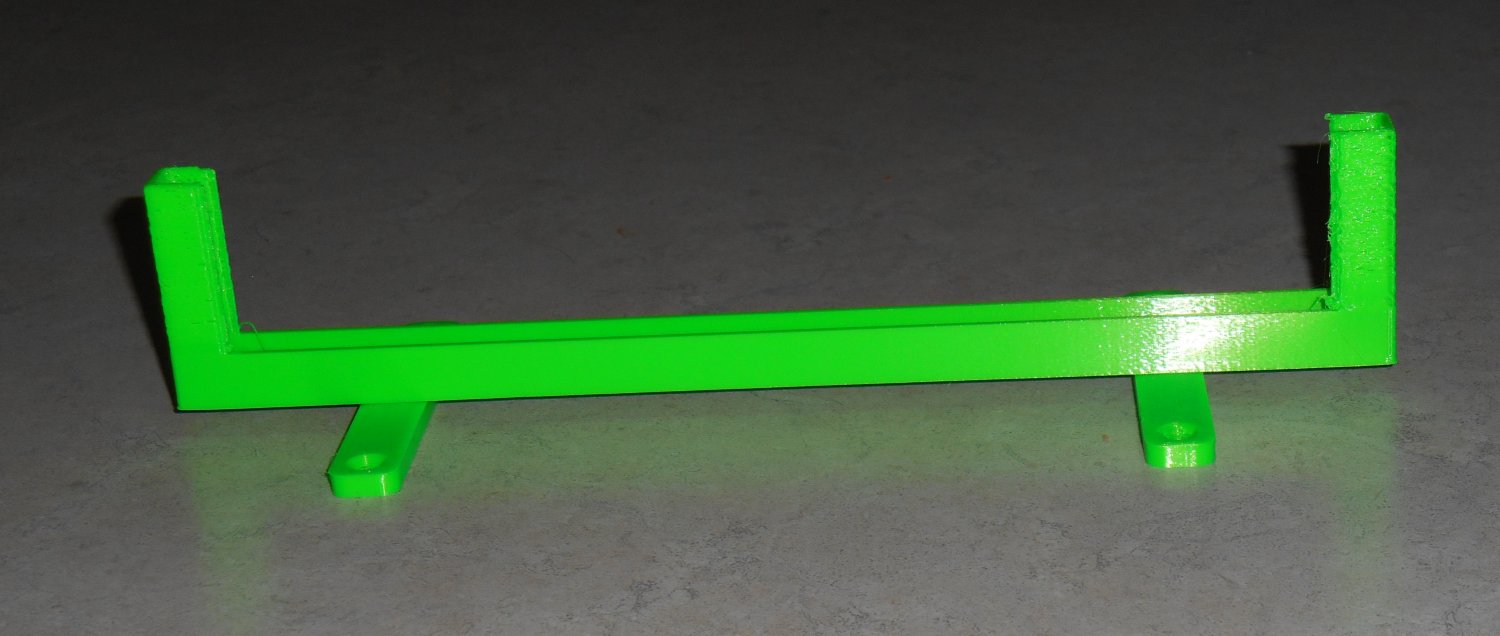

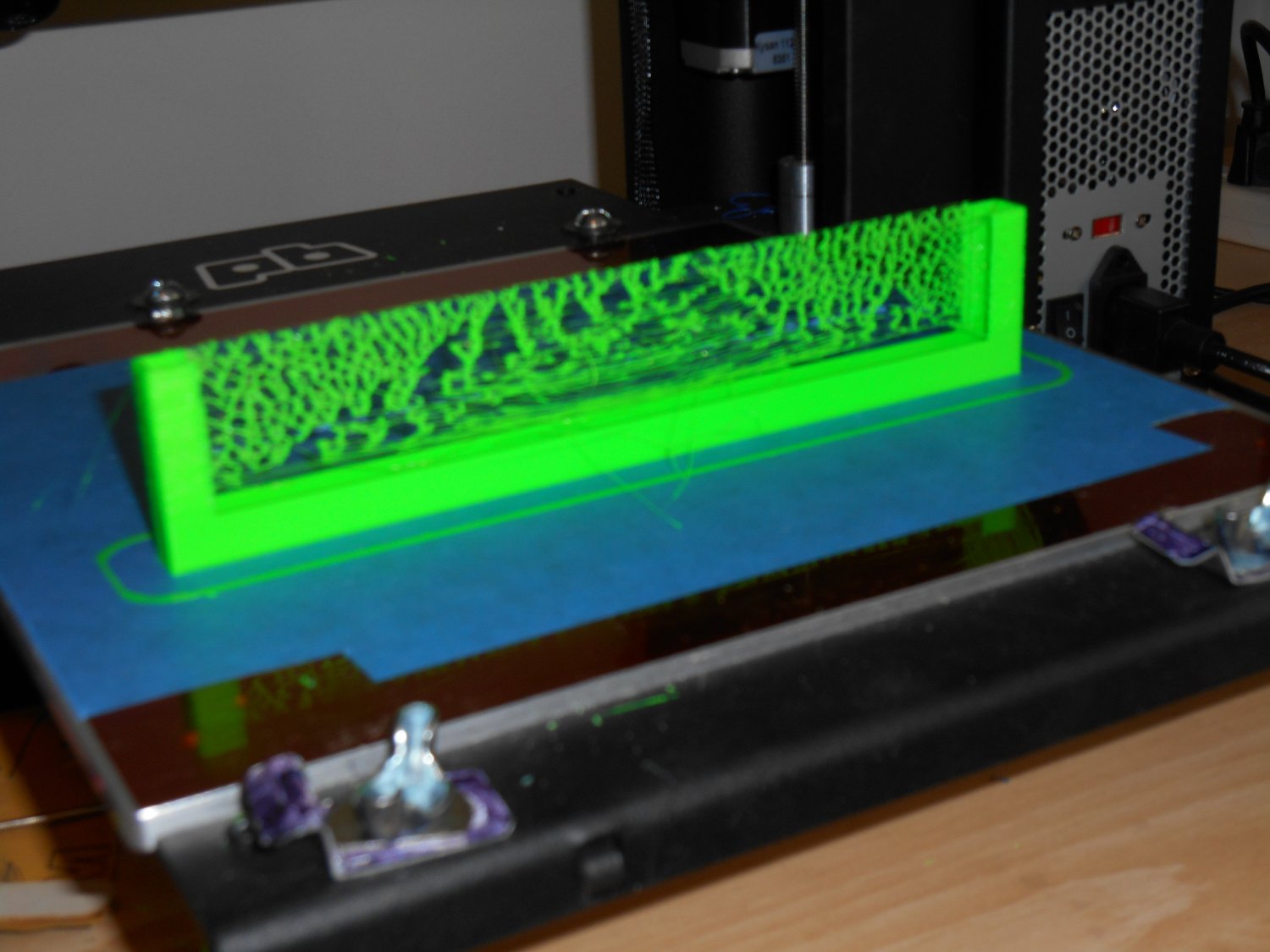

The photos below show my 3D printed stand. The legs are not solidly printed on the long beam. They are attached with 4-40 machine screws so that they can pivot 90°.

I’m still a little bit concerned that it may be unstable. I tried to make 3D printed suction cups using Ninja Flex however the rim of the cups was not smooth enough to make an airtight seal. I ended up buying some suction cups from Amazon but they have not arrived yet. I’m not sure if I’m going to install them or not.

One other item to share… I must’ve been using some really cheap PLA plastic that was very stringy because as the stand was being printed there was an unusual amount of threads connecting the two uprights. The end result looked like some sort of weird tennis net. I’ve never seen threading this bad. Of course it was easily broken off and removed but I thought it was so bizarre I had to share it.

I been using the device for a couple of weeks now and it works really well. It allows me to not hesitate to roll over on my side where I can sleep more comfortably and know that if I need to communicate with my dad I can do so easily.

I talked about this project on the weekly Adafruit Show-And-Tell video chat. You can see that video by clicking on the icon on the right.

Demonstrating New iOS 10 Switch Control Features

There are several new features for accessibility switch control in iOS 10 that I thought I would demonstrate. One is an easier way to rearrange icons on your desktop. The other is a way to control multiple iOS devices using one Bluetooth switch device. Suppose you have an iPhone and an iPad and you want to use the same accessibility switches to control either one. In the past you would have to unpair one of them and pair the other one. This had to be done manually and could not be done by switch control. However if both devices are connected to the same Wi-Fi you can control one through the other completely under switch control. Here are the videos.

The Ultimate Remote is Dead. Long Live the Ultimate Remote 2.0

In late 2015 I built a piece of assistive technology that I called my Ultimate Remote. The device was an infrared remote for controlling my TV and cable box. It also had infrared mouse control for my computers. There were also limited keyboard commands mostly arrow keys, enter key, backspace and some control keys for doing cut-and-paste. Finally it was a Bluetooth device for doing accessibility switch control on my iPhone. I wrote about it in this blog post from January 2016.

The core of it was an Adafruit Micro BLE device which was discontinued shortly after I purchased it. Adafruit replaced it with the Adafruit Feather 32u4 BLE. The Micro BLE also had an ATMega32u4 which is one of my favorite 8-bit processors.

The display was a monochrome 1.3 inch 128×64 OLED graphic display. It also contained one of my infrared I/O boards although it only did output. I didn’t really need to read any IR codes. On the end of a long wire were three lever micro switches that I would hold in my right hand to control the device.

The device served me well for well over a year. It was critical to me during my recent hospital stay where I was on a ventilator and could not talk. I used the switch control to type notepad messages on my iPhone and communicate with the nurses and doctors. You can read about that adventure here.

The micro switches have always been the weakest link in my devices. I have to use switches that have a feather touch to them and that means they are very fragile. The switches get knocked around quite a bit and so it was inevitable that one of them would break. About a week ago one of the switches failed and we had to replace them.

I had planned for many months to rebuild the entire device. I had used up all of the program memory in the device and could not add any new features or any new IR commands. I did not have codes installed for my Blu-ray player and there wasn’t any room left. In fact one time I had tried to recompile the code and because one of the included libraries had been updated, the code wouldn’t fit anymore. I don’t know if it was the Bluetooth BLE library or the graphics display library but something changed. I had to go through my code and try to free up some space by eliminating some error messages or shortening other messages. I finally got it to recompile but the writing was on the wall that I needed to upgrade.

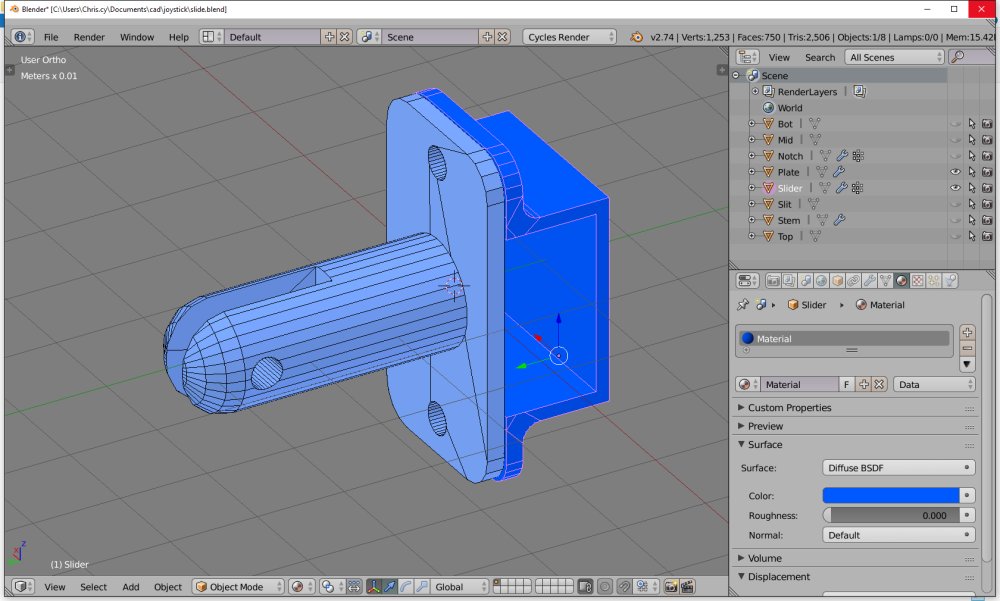

The obvious choice was to use a new Adafruit Feather M0 BLE. Instead of the traditional 8-bit 32u4 running at 16 MHz with 32K flash memory and 2.5K RAM, I would have a 32-bit ARM Cortex M0+ running at 48 MHz, with 256K flash memory and 32K of RAM. The main problem was that my infrared library IRLib did not support these newer 32-bit ARM processors.

I had just recently spent weeks researching the new processor and converting my infrared library to support the newer chips. The timing and frequency modulation portions of my IR code are extremely dependent on the internal timers of the processor and that is very hardware dependent. I had to learn a whole new system of timers and PWM frequency control to rewrite the code. Fortunately I got it running just in time.

Although I had the infrared code working on the new processor, and had a Feather M0 BLE available to build a new device, it should not have been necessary to rush the new device into construction. All we had to do was repair the old remote by replacing the micro switches. I already had another set of switches assembled in anticipation of building the new remote. All we had to do was cut the cable on the old one, splice in the new cable and everything would be fine.

Dad decided that rather than having a stiff, unsightly splice in the middle of my cable, he would open up the box, unsolder the old cable and solder on the new cable. He ended up completely disassembling everything to get at the wires that needed replacing. I appreciated that he would go to that trouble even though this device was going to get replaced probably in a month or two. Unfortunately this was a bad decision.

Above are photos of the interior of my original ultimate remote. As you can see the wiring is pretty complicated. Unfortunately I only have about four different colors of wires available so we had to use the same color wires for different purposes. For example there are multiple green wires used for different purposes. After replacing the cable to the micro switches, dad tried to plug everything back in the way it was. We plugged in the device and I tried pushing the buttons but nothing would happen. In the course of trying to figure out what was wrong he touched one of the infrared LEDs and discovered that it was very nearly becoming more red than infra. It was too hot to touch. Although we did not get a visit from the infamous “Blue Smoke Monster”, if we had left it connected very long we would’ve had at least smoke and possibly fire as well.

It didn’t take us long to find out that the culprit was 2 green wires that had been crossed. We fixed the wiring and plugged it back in. No heat this time. The device worked intermittently for about five minutes and then quit working altogether. It was obvious that we had burned out the IR LED at least and possibly the transistors driving them.

Fortunately I had sufficient parts to build a new IR output board so we spent the next afternoon building it and installing it. It would not work either! One of the problems we were facing was that we had assembled and disassembled the box many times. I had been using small gauge stranded wire with silicone insulation. That is very flexible and made it easy to route the wires in a tiny box. However several of these wires were soldered into through hole locations on the circuit boards. Right at the point where they are soldered in, they are extremely susceptible to breaking if they are bent back and forth too many times. A better solution would have been to put a header pin in the hole. Then we could solder the stranded wire onto the pin and cover it with a piece of heat shrink tubing. At this point it was too late to do that.

We tried repeatedly to diagnose the problem with the new IR board but every time we fixed one thing, something else would break. There was also the possibility that we had damaged the Adafruit Micro BLE board itself. As I mentioned earlier, that board has been discontinued so there was no possibility of replacing it. After two full afternoons of working on it, I decided to throw in the towel and put all of our efforts into building the completely new device that had been planning for months.

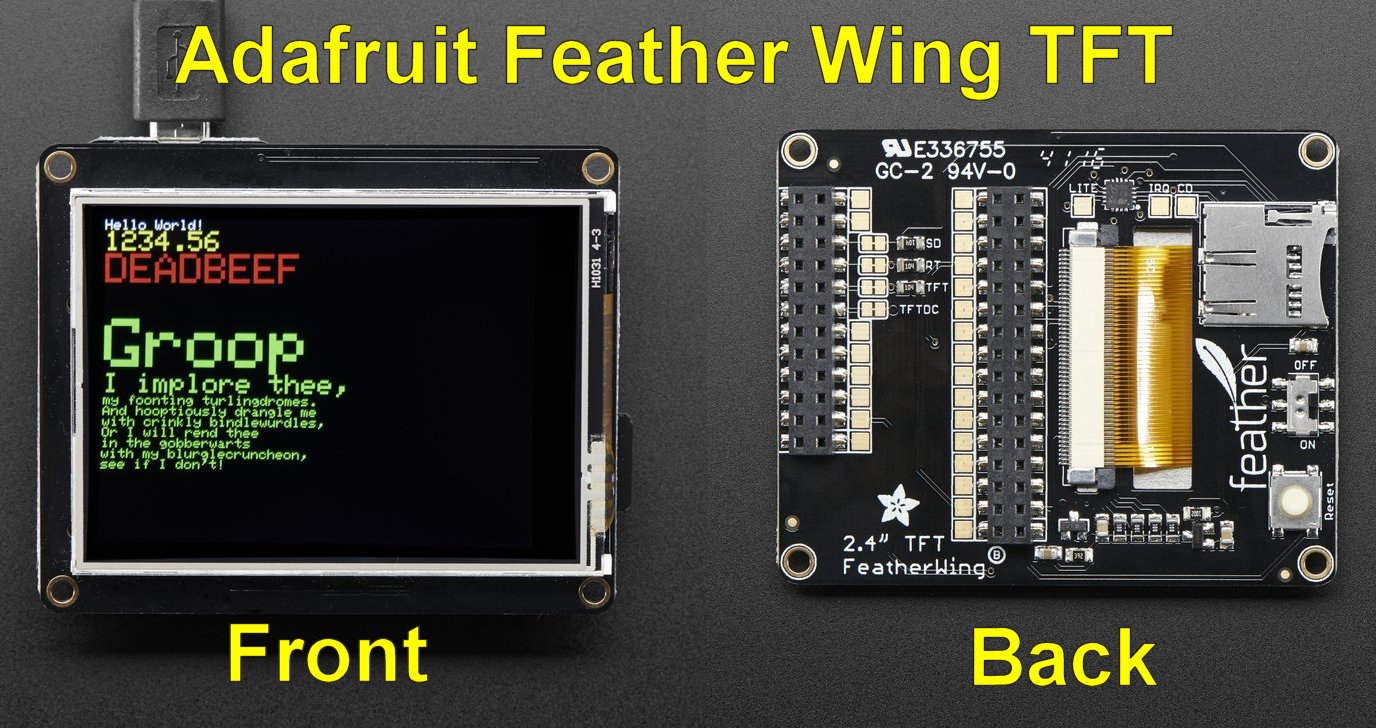

I had all of the necessary parts. The new device would have a much larger 2.4 inch TFT color graphics display instead of the 1.3 inch monochrome OLED. This device also features a resistive touchscreen however I don’t have any use for that feature. It also includes a slot for an SD memory card. I may come up with a future use for that.

One of the nice things about the Feather Wing TFT board is that the feather board plugs into a socket in the backside. You don’t have to run wires from the main processor to the display board. However one of the disadvantages is that there is only one power and one ground pin on the device. So I was going to have to cut up a little piece of prototype board to make a power and a ground bus. This would bring in power from the outside, connected to the Feather and display boards, and run power to the infrared board. Similarly I needed ground wires to all of those parts plus a ground wire for the micro switches. We also needed to solder a jumper so that I can turn the backlight of the display off and on. There is a solder pad available but you have to jumper it to one of your Feather pins.

Although the Feather boards have a built-in battery connector and a battery charging circuit, I decided to power the device from an external 5v battery source. My old Ultimate Remote was a 5v device throughout while the Feather system runs on 3.3v. In the old system I had a short cable with a barrel jack running from the remote into a battery pack I call a Printy Boost. The Printy Boost is a device which I designed for the Adafruit Learning System as seen here. The Printy Boost also provides extended battery life to power my iPhone. So rather than have a separate battery for the remote and for the iPhone backup power I decided I would stick with the old system and run a cable from the Printy Boost into the remote just like I did before. Rather than connect to the +3.3v pin I connected to me “USB” pin which was the same as powering it through the USB cable at 5v.

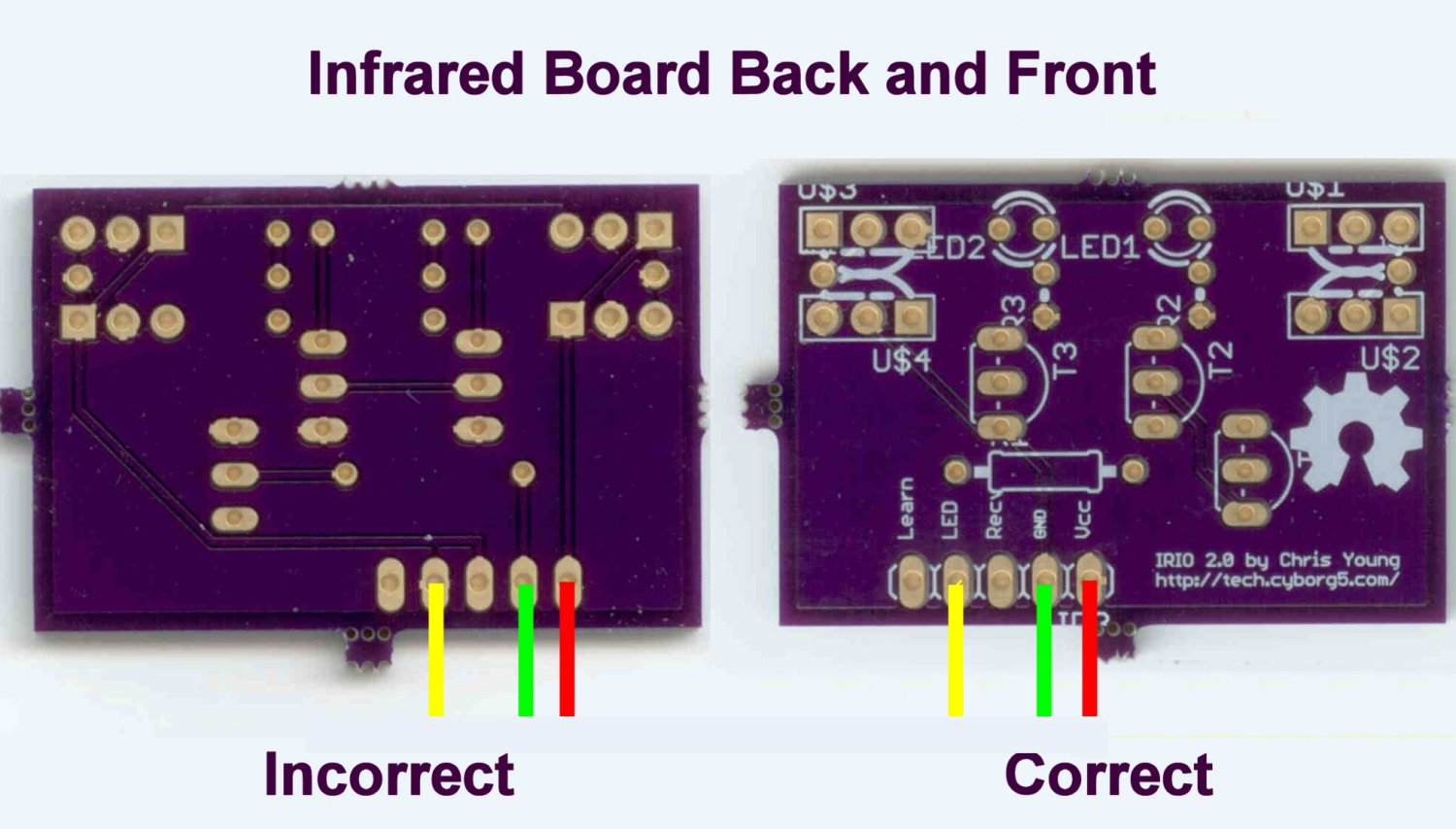

There are some differences between the Feather TFT board and the old monochrome OLED graphics board so I had to tinker with the software to get things to run. Most of it was compatible because Most of the Boards operate on the Adafruit Graphics library but there are still differences. Once I had display software converted I tried using the device. Unfortunately it didn’t work again! You would think I would be more careful about crossed wires after the previous fiasco. It turns out we had the infrared I/O board wired backwards. I had drawn the wiring diagram looking at the front side of the IR board. That means on the right 2 pins are power and ground. Then moving to the left you skip one pin and the next one is the IR output. However the way the board is oriented in the device, the backside of the board is facing upwards. We wired it with power and ground on the right but that was wrong. Fortunately this just meant that the power lines were going to the receiver pins which were not being used in this application. So nothing burned out. We reversed the wiring and everything worked fine.

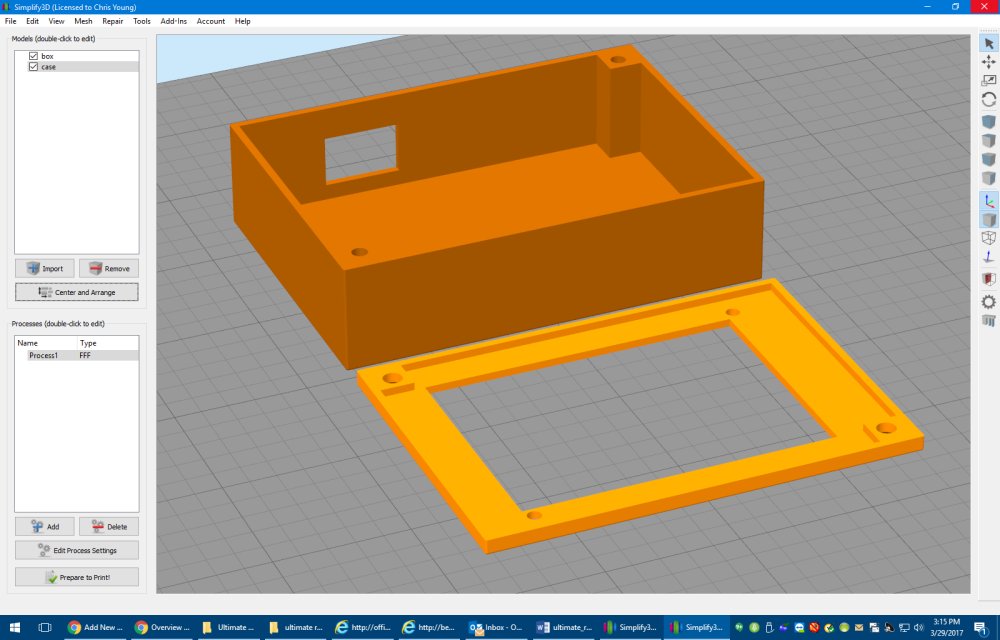

The final step was to design a 3D printed enclosure for the device. That took another afternoon or so.

We mounted the TFT display into the lid of the box using black nylon plastic screws and nuts out of this kit sold by Adafruit. They are really handy because they are selected to fit in the 0.1 inches diameter mounting holes used in most Adafruit boards. When that box of screws was first added to the Adafruit catalog I knew I would need them someday and purchased it right away. They work perfectly so it was a great purchase.

The rest of the box is held together by 5/8 inch sheet metal screws. I like using sheet metal screws because they have a pointy end that taps really well into 3D printed PLA plastic. Here are some more photos of the completed project.

There are still lots of software tweaks I have to implement. It takes longer to erase a 320×240 color display than it does to erase a 128×64 monochrome display. The monochrome device required you to call a “display” method to update the display after writing to it. The new color device updates as you write to it. The result is you can see the screen update where the old one would update instantly. I think the updates actually slow down the entire process a little bit. So I’m going to have to optimize the code so that it only updates the screen when absolutely necessary and only does it in small pieces. In the old system it was easy to just erase everything and redraw it from scratch every time but that won’t work very well in the new system.

Of course I also have to add all the features I’ve been wanting to add but didn’t have sufficient memory under the old system. I have to add all the codes for my Blu-ray player and there are some additional keyboard codes that I want to add. I may end up implementing an entire keyboard system so that I can type anything using IR codes. I’ve developed a special protocol for my IR library that allows me to use any mouse or keyboard commands possible. I’ve only been using a fraction of that capability.

One other difference between the old and new system involves the power output of the IR board. When I originally designed my infrared I/O board I ran the LEDs with no current limiting resistors. Because the LEDs are only intermittently running (assuming you don’t cross your wires), it’s safe to put more than 1 amp through them. But my experience is that sometimes USB power can’t supply enough power when that current spikes during transmission. So I’ve added some 33 ohms current limiting resistors in line with the LEDs on the latest version of my infrared I/O board. The old device did not have these resistors but it ran well because it was powered by a battery pack rather than a USB plug. Now that I’ve worked with the new remote I’m realizing it doesn’t have the power of the old one. I’m going to try shorting across those resistors and see if it helps.

I still have fond memories of my original Ultimate Remote. It served me well for over a year and was literarily a lifesaver while I was in the hospital. But I’m also looking forward to the new things I will be able to do with the new improved Ultimate Remote 2.0.

Afterward: After I completed the project I presented it on the weekly Adafruit Show-and-Tell. I was the first guest in the video below.

On a Roll at Last!

In this installment, I cover the fourth week of working on my new wheelchair. We will solve one problem and immediately create another one.

Free at Last

Our story is now up to Monday April 18, 2016 exactly 3 weeks since my new wheelchair has arrived and I still haven’t been able to drive it myself yet. It was my own fault because in an attempt to reprogram it, I accidentally disabled the joystick and locked myself out of the programming. Today was the day that the technician was supposed to come and fix it but I didn’t have high hopes. I’ve faced so many disappointments that I try not to get too psyched up.

The technician who arrived was Aaron and he was one of the 2 guys who had delivered the chair weeks ago. I had thought that the guy I had dealing with Patrick also did repairs but according to Aaron, Patrick is really just a salesman and Aaron is the repair man. He had with him a small black box with a cable coming out of it that looks like this one that I found on eBay. They call it a programming dongle. It is supposed to let you get into various programming modes that cannot be reached just by pushing the buttons on the display module.

There is a cable running from the display unit to the controller box on the back of the chair and it has a jack and plug in the middle of the cable. You unplug it and plug this box in line where the cable comes apart. The hope was that simply plugging it in would free things up and allow him to enter programming mode again. Unfortunately that didn’t work. So he got on the phone and called Sunrise Medical technical support. We waited several minutes on hold until we got a live person and then they had to transfer us to the right person to answer the question which meant several more minutes on hold. When we told the guy what the problem was he basically said we were screwed. He said if plugging the dongle in didn’t free it up then he would need the diagnostic tool. There’s apparently another handheld module that dealers have called a diagnostic tool. It has its own little LCD screen and buttons that not only allows you to reprogram a wheelchair perform diagnostics as well. Aaron had already told me that they only had one of those such devices to pass around between 7 different repair technicians and currently it was broken. The guy on the phone said if we could hook the dongle into a PC we might be able to get it to reset the software. So we hung up from him and tried to decide what to do next.

Aaron didn’t have the cable necessary to connect the dongle to a computer. He would have to go back to the office to get one. Of course why he was sent out to reprogram a wheelchair and didn’t have the proper cable is a question we never answered. Anyway I had seen such cables online during my research. They had USB on one end but I didn’t know what they had on the other end. I presumed it was some sort of weird connector like the one you can see in the photo that connects all of the various parts of the R-net wheelchair control system. Then I happen to see the end of the dongle and immediately recognized the jack was a standard USB “A” style jack. These are the full-size square USB jacks that you find on some computer printers and scanners. They were the original USB before they made micro and mini USB jacks. I said “is that where you plug in the computer cable?” And he said yes. I’ve got a whole box of those and every other kind of USB cable you can think of. I also had plenty of computers available and I knew where to find the software we needed online.

Aaron didn’t have the cable necessary to connect the dongle to a computer. He would have to go back to the office to get one. Of course why he was sent out to reprogram a wheelchair and didn’t have the proper cable is a question we never answered. Anyway I had seen such cables online during my research. They had USB on one end but I didn’t know what they had on the other end. I presumed it was some sort of weird connector like the one you can see in the photo that connects all of the various parts of the R-net wheelchair control system. Then I happen to see the end of the dongle and immediately recognized the jack was a standard USB “A” style jack. These are the full-size square USB jacks that you find on some computer printers and scanners. They were the original USB before they made micro and mini USB jacks. I said “is that where you plug in the computer cable?” And he said yes. I’ve got a whole box of those and every other kind of USB cable you can think of. I also had plenty of computers available and I knew where to find the software we needed online.

As it turned out he did have his own laptop with the proper software already installed. I provided the cable and we hooked it up. The software didn’t see my wheelchair as being connected. When you would plug the USB cable in, windows would make the usual noise that you hear when you plug a USB device into a Windows PC. But the software had a status window that said “no connection”. We made another call to Sunrise Medical Support and went through the same two-step waiting on hold process that we had been through previously. One of the problems was that Aaron wasn’t that familiar with the software and thought perhaps there was something he should have been clicking on to get it to connect. We finally got through to the support guy and explained the problem. We were doing everything right so it had to be a driver problem.

Before the guy on the phone could explain what to do about drivers I said “I’ve got this”. I instructed Aaron how to call up the Windows Device Manager window and sure enough under USB devices was “R-net Dongle” with a little yellow triangle next to it. I told him to right-click on it and it said “this device is not operating properly”. No shit. I had him click on the “Update Driver” button and it asked did we want to specify where to look or have it look online itself. If I had to bet money on it I thought we would have to go to a website to find the proper driver and install it ourselves. For such an obscure device I didn’t think it would do an automatic update but I figured we would give it a try. Meanwhile the guy on the phone was trying to figure out where to tell us to go to download the driver when much to everyone’s surprise the computer said “Installing new driver”. A minute or two later it completed. We went back to the software and sure enough it said “connected”!

Then the guy on the phone walked Aaron through what to click on to reset the factory defaults. That all went very smoothly and when it was done, the joystick worked perfectly. I asked Aaron if we needed to calibrate this joystick and he didn’t think that we needed to. At some point I’m going to get ambitious and go through the joystick calibration procedure in the manual but for now the joystick seemed to be working. We put my newly 3-D printed homemade collar around my neck and at 3:50 PM on Monday April 18 I finally got to drive my wheelchair for the first time. Here is a video I shot a few minutes later after Aaron left.

It was 328 days since the salesman and I first began working on the purchase of a new wheelchair and I finally was able to drive it. As I said in the beginning, it had also been three weeks to the day since the chair had arrived as well.

Happy Birthday to Us

Not only was April 18 the first day I could drive my wheelchair, it also happened to be my dad’s 82nd birthday. It felt like a double birthday to me. Normally we would go out to dinner to celebrate but we weren’t yet ready to have the wheelchair in the van so we decided to get carryout from the Golden Corral Buffet. It’s an all-you-can-eat buffet but neither dad nor I have a big enough appetite to make it worth the money. You can however go in and fill up Styrofoam containers with food and then they weigh it and charge you by the ounce. He can fill up a couple of containers with enough food for both of us and the cost turns out to be barely over half of what it would cost if we both went into the restaurant in the all-you-can-eat system.

My favorite is their rotisserie chicken. I think they must brine it before cooking or something to get the flavor of the spices to soak in. I absolutely love it. I have a lot of trouble eating skin whether it is fried or baked chicken and a lot of the time that’s where all the flavor is. But here the flavor goes all through. Unfortunately this particular day they didn’t have the rotisserie chicken so dad just got me a slice of pizza, some large steak fries and a large brownie.

While dad was going to get the food, I put together the YouTube video of me driving the chair that is embedded above here. While he was gone I also just drove the chair all over the house. I almost felt like dancing so I put on some music. I didn’t exactly drive in time with the music but I just wanted to celebrate a kind of birthday of my own. It was the rebirth of my mobility.

What’s Skew?

We had discovered that when I go into the van it’s too difficult for me to lean forward to duck in the doorway like I previously did in my old chair. I sit about an inch or so higher in this chair than in the old one and I just can’t duck far enough. We had discovered however that if you remove the headrest and I tilt my head backwards, I could just barely make it into the van. I have to be perfectly centered however because on the right side there is a brace on the lift on which I could hit my head. When I lean my head back, my neck hits of the top of the backrest of the wheelchair. If we could lower the backrest slightly, I would be able to tilt my head back further.

I had originally anticipated that to get in the van I would simply recline the wheelchair and not have to worry about ducking. However the process of reclining isn’t quite as straightforward as I hoped it would be. You switch the chair out of driving mode into seat positioning mode and then you have to select which seat function you want to adjust. You have to select whether it is recline, tilt, combination of both, or footrest adjustments. In broad daylight the LCD display screen washes out and you can’t see what you’re doing. Also in order to recline we need to adjust my seatbelts because as I start to lean back, my chest belt tries to tighten up on me. It was just more complicated than we had hoped. Taking out the headrest, laying my head back, driving in, and putting the headrest back in place seemed a lot simpler. But to make it safer we really want to lower the backrest so I could lean my head back further.

One of the things that makes this chair so complicated is that it is so adjustable. It used to be they made wheelchairs in perhaps two sizes and then it was up to you to come up with cushions or padding to make you fit the chair. These days the chairs are insanely adjustable and that along with the tilt and recline mechanisms it makes them insanely complicated.

There is a procedure in the user manual that shows you how to remount the backrest into a lower mounting hole. We had talked to Aaron about the possibility but he said it couldn’t be done in my case because it would mess up the skew mechanism. That left me with a question “What’s skew?” (To which the comedian in me would reply “Nothing… What’s skew with you?”)

The reclining mechanism is quite complicated in that it has 2 actuator motors. One of them does the actual reclining. The other one slides the backrest down slightly as you recline. That keeps the backrest stationary relative to your back as you lean backwards. I would have to create a complicated animated illustration to fully explain why it does that and at this point of the story we really weren’t sure how or why it worked. It is this second sliding mechanism that is known as the skew mechanism. When they delivered the wheelchair it had a backrest cushion that reached all the way down to the seat. We concluded that it was this tall cushion that was the reason he said it could skew properly. We had already replaced it with a shorter backrest cushion that had plenty of room to slide up and down. There was another set of mounting holes that would allow us to lower the seat. It might’ve been just as easy to get out the sawzall and cut an inch off the top but you hate to do that if there is an adjustment that will work. Also we weren’t really sure we needed it. I did fit through the door. It just didn’t have any margin for error. We also still had the option to simply recline the chair. The skew mechanism turned out to be one of the reasons why the safety belt was messing up during reclining. Perhaps reclining was a better solution after all. We later found a way to remount the safety belt so that it didn’t get affected by the skew.

As you have probably seen after reading these blogs or my recent essay on my choking and swallowing difficulties, I have a tendency to tell every single detail of any story. But I’m going to spare you some of gory details of this one. The short version is that dad tried to follow the procedures of the manual to disconnect the actuator, disconnect the seat hinge, reposition the seat hinge, and reconnect the actuator all in a lower position. He started working on it the evening of the 18th after I was in bed. He spent hours trying to do it that night and the next morning. We finally had to give up and put things back the way they were. That is almost…

On paper, the process seems pretty simple but in addition to the hinge and the recline actuator that need to be moved, there is a gas filled cylinder that looks like a shock absorber but is actually a very stiff compression spring. He could not get the spring compressed sufficiently to get it connected the proper hole. When he gave up and put it all back together, the spring was one hole lower than it should’ve been. It simply would not go back in the proper hole. The mechanism still seemed to work smoothly after he put it back together so we just gave up on it.

The Tortoise Beat the Hare

I had a sleepless night that night. Part of it was excitement over the day’s events. Part of it was the noise of dad banging on the bolt trying to get it back in as he was adjusting wheelchair 🙂 Anyway I slept in until 1 PM on Tuesday. We canceled the home health aide and dad got me dressed and I had a small snack about 2:30 rather than eating lunch. As he was stressing me, dad explained everything was back together but a new problem had arisen.

The chair wouldn’t drive except at the lowest speed. A little orange icon in the shape of a tortoise had popped up on the LCD display. The speed control shows icons of either a tortoise on one end or a hare on the other end. Apparently those are the new universal symbols for slow or fast. If you would set the recline angle of the chair up 100% vertical, the tortoise would disappear and you could drive at any speed you wanted to. But if you recline even a couple of degrees, the tortoise would pop up and you would be limited to the lowest speed setting.

Is a safety mechanism to keep you from driving the chair rapidly while in a reclined position. If you recline very far, the tortoise turns red and you cannot drive at all. We had seen it before but it usually didn’t kick in until 20-30 degrees or so. However my comfortable seating position is about 5 degrees reclined. Something that we had done along the way had messed up this mechanism.

So in this little fable my dad and I have been the hares. A couple of weeks ago I had rushed like a jack rabbit into changing the programming and messed things up. Dad had rushed into the mechanical adjustments and apparently messed things up as well. And we were now being beaten by a damn little tortoise icon. I guess the Aesop fable was right. The tortoise beat the hares again.

Is an earlier installment I had described my dad and I were like Liam Neeson in the “Taken” movies who were dangerous because we “possessed a particular set of skills”. As it turns out we both should’ve been listening to another deep-voiced badass movie character Clint Eastwood in the second “Dirty Harry” movie when he famously said “A man’s it got to know his limitations.” Or perhaps it was like Tom Cruise in “Top Gun” getting chewed out by his commander Stinger when he said “Son, your ego is writing checks your body can’t cash.” Whatever fable or movie was appropriate to the situation, the score was even. Dad and I had both screwed up.

Actually at this point we weren’t completely sure that he had done anything wrong. We had unfortunately violated my mother’s proverb that I spoke of earlier about “don’t feed the baby 2 new foods”. There was a possibility that resetting the software that we had done with Aaron earlier in the day had reset the calibration of the tilt sensor. I was pretty sure that the chair had been driving normal speed when I drove it around that evening but we really weren’t sure whether it was the software reset or the change of the mechanics that was the root of the problem.

I sent an email to Aaron and I also posted messages on the wheelchairdriver.com discussion forum. The people online said that the sensors are pretty flaky and have been known to give out at inappropriate times such as when you are a mile from home and suddenly your wheelchair starts going a tortoise pace because it thinks you are reclined when you are not. The bottom line from them was it could be software or it could be hardware they couldn’t tell for sure.

Rather than tell the remainder of this story chronologically day-by-day as I have been doing, I’m going to finish out this topic because we did not get this resolved until eight days later on Tuesday April 26.

The email reply I got from Aaron basically said what everyone else had said. It could be software… it could be hardware… he didn’t know. So I wrote back and said “So what do I do to resolve this?” I never heard back from him. I spent a lot of time over the next several days trying to research how the sensor works, where it’s located, does the software calibrate it? I tried sending email to Sunrise Medical who manufactures the chair. Experience had shown me that Aaron couldn’t do anything without calling them. Maybe I could get some answers directly. I did get an initial reply. They said they needed to know the serial number on my wheelchair before they can answer any more questions. I sent it to them with more information about the problem. I never got a reply.

On Monday April 25th we finally called National Seating and Mobility to get them to officially send Aaron or some other technician out to look at it. Apparently he wasn’t going to reply to my emails unless I got his office involved. They gave me the same story of either bring it in or wait another week until we can send someone. Rather than wait another week dad took it in the following day. They tried a couple of different things to no avail but eventually went back to work on putting the spring cylinder back into its proper hole. It took two guys to do it which was why my dad had spent so many hours trying to do it himself. For some bizarre reason it fixed the problem. The technicians couldn’t believe that that was the problem and neither could we. There’s nothing electronic connected to that cylinder. There must be some sort of pressure sensor in the actuator motor that could tell that the spring was not set properly and that was messing things up.

During the entire week that the speed control was messed up, I chose not to drive the chair myself. It was too difficult to drive at that speed and I was having some other issues with my joystick mount that I will describe later. So even though I did get to drive the chair for a single day three weeks after its arrival. I did not really have the chair fully operational until exactly 4 weeks and one day after its arrival.

In the end, the seat was back where it was originally and all of that adjustment was for nothing. And for reasons which I will explain later… I’m still going to have to recline the wheelchair to get in the van. All of that adjustment was for nothing. The reasons why I have to recline is a story for an entirely different blog.

Showing Off

Adafruit Show-and-Tell sticker I earned for this presentation.

Despite the fact that the tortoise had sent this hare sadly strolling away with his tail between his legs, I want to celebrate and show off that the chair was working even if it wasn’t completely up to speed. Every Wednesday night my maker supplier Adafruit Industries has a weekly online video chat where people show off their electronics and other maker projects. A few weeks earlier I had shown them a sort of work in progress version of my joystick mount. That was back when we were just making modifications to the mount that had the cloth strap. This was the new completely redesigned built from scratch system. And rather than just show a slideshow of pictures, this time I could actually demonstrate the project myself. I was going to drive my wheelchair live on the Internet for hundreds to see.

I did some tests to see what would be visible on my WebCam. I could park in front of the camera and then back up the chair and do some small maneuvers and then pull up to the computer again. The demonstration went really well and they were impressed. One of the hosts of the show Phil Torrone was very impressed. He said that so many of the 3-D printer projects that they encounter are somewhat trivial trinkets. They are typically little knickknacks or toys or perhaps they are just enclosures for electronics projects. Indeed that’s the majority of what I’ve done with my 3-D printer. However this was a project that really did something useful that would be difficult to do without a 3-D printer. The fact that the commercially made devices would not meet my specific needs but that I could create something with a 3-D printer was a much better illustration of what 3-D printing was all about.

The guy who presented after me also had an inspiring project to show. He was getting treatment for a brain tumor and he has some sort of electronic device wired into a cap that he had to wear on his head. The electronics were stored in a backpack. For various reasons from time to time he would shut the device off but he would occasionally forget to turn it back on again. There was a little blue light that would be on anytime that the device was operational. He built an electronic gadget with a color light sensor that would detect whether or not the light was on. If it was off for too long of a time period, it would ring an alarm. Here was an electronic medical device probably worth thousands of dollars and it didn’t have an alarm function. This guy build one himself out of parts purchased from Adafruit.

Here is the video on YouTube. My section starts at 5 minutes 10 seconds into the show. The guy with the alarm on his cancer equipment is immediately after me.

After the group show-and-tell, they also present an hour-long live streaming program called “Ask an Engineer” which includes maker news, tips, and a Q&A section where you can ask engineer and Adafruit founder Limor “Ladyada” Fried your engineering questions. But part of the “Ask an Engineer” show begins with a recap of the previous “Show-and-Tell” program. In that program they also reiterated their appreciation for my use of 3-D printing to solve a real problem. You can see the “Ask an Engineer” program here. That link takes you to the 11 minute mark where she described my project but if you bother to watch it you might want to skip ahead to about 14 minutes where they comment further. I’m writing this blog on May 3rd and as of this point the Show-and-Tell has been seen over 1000 views and the engineer show has been seen on YouTube over 2000 times. The show also streams live on periscope, twitch, u-stream and other platforms. Of course I always tell people they can visit this blog for more information.

Promoting my work on the Adafruit programs has led a number of people to contact me about my projects. I know of three or four people who were building specialized infrared remote controls for their aged or disabled friends and family. They have contacted me for advice and I’ve really enjoyed helping them with their projects. Perhaps sharing my wheelchair stories will also help other disabled people who are makers or firms of makers

I was going to continue telling the story of some design modifications that I’ve made on the joystick mount while I was waiting on the reclining problem to be fixed however I think this is a good place to wrap up this edition. In the next installment I will talk about some modifications to the joystick mount that were made during the fourth and fifth weeks of having the new wheelchair.

Groundhog Week

In this installmenpurposet we will cover the third week of working on the new wheelchair. We work on 3-D printing parts for the joystick and waiting on word from the wheelchair people about my programming glitch.

S.S.D.W.

I called this installment “Groundhog Week” after the movie “Groundhog Day” in which Bill Murray repeats the same day over and over again. I sort of feel like this week is a repeat of the previous week. Better cliché title for this week is the abbreviation “S.S.D.W.” There is a common saying that people often abbreviate using the letters SSDD. It stands for “Same Shit, Different Day” and is used as a way to say one’s life is boring and monotonous and not particularly satisfying. When I went to write the opening paragraph for this installment of the blog I started by editing the intro from the previous installment. I realized that all I needed to do to make it accurate was to edit the words “second week” so it would read “third week”. So the title of this segment is “Same Shit, Different Week”.

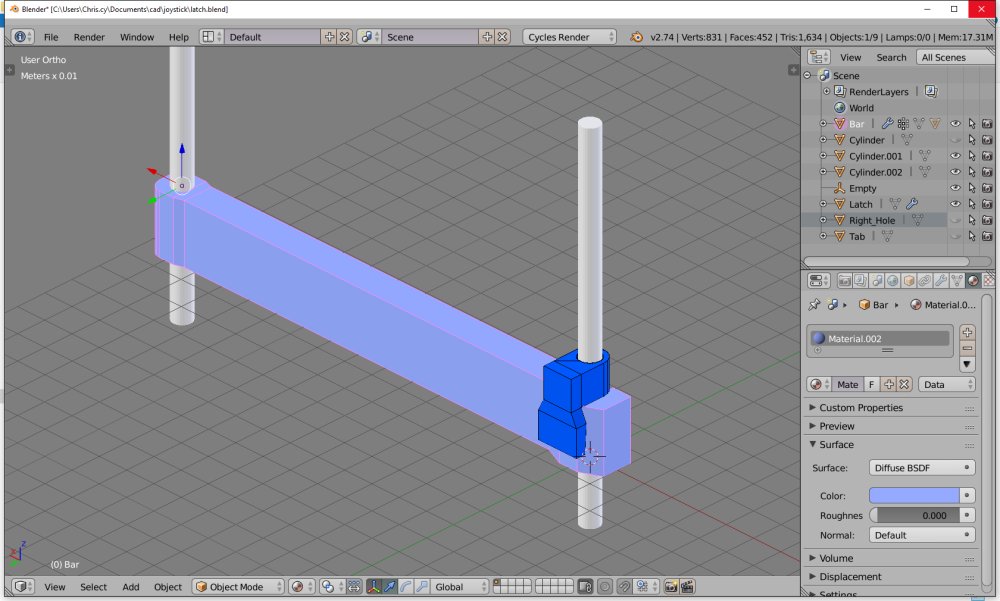

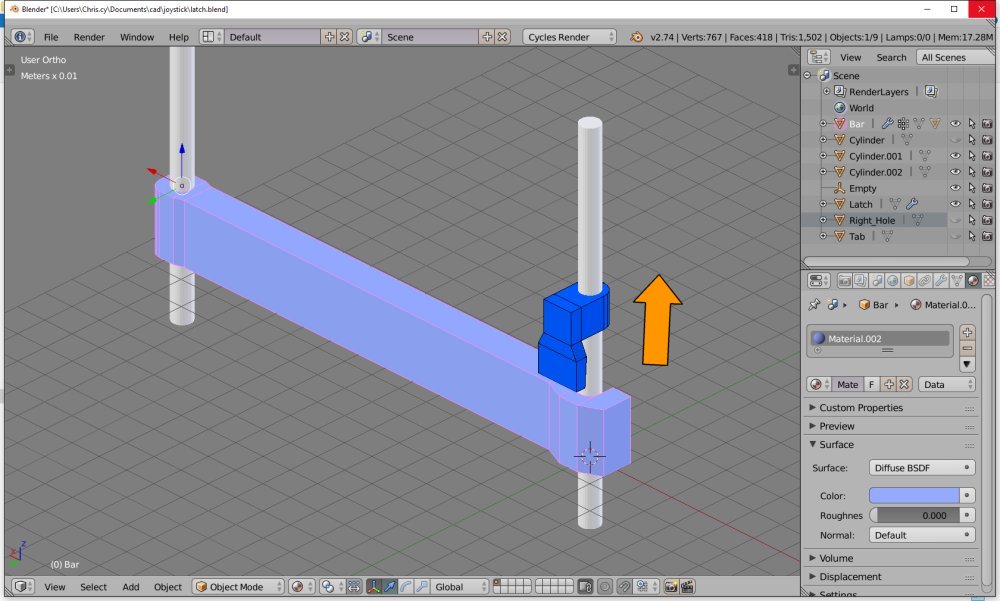

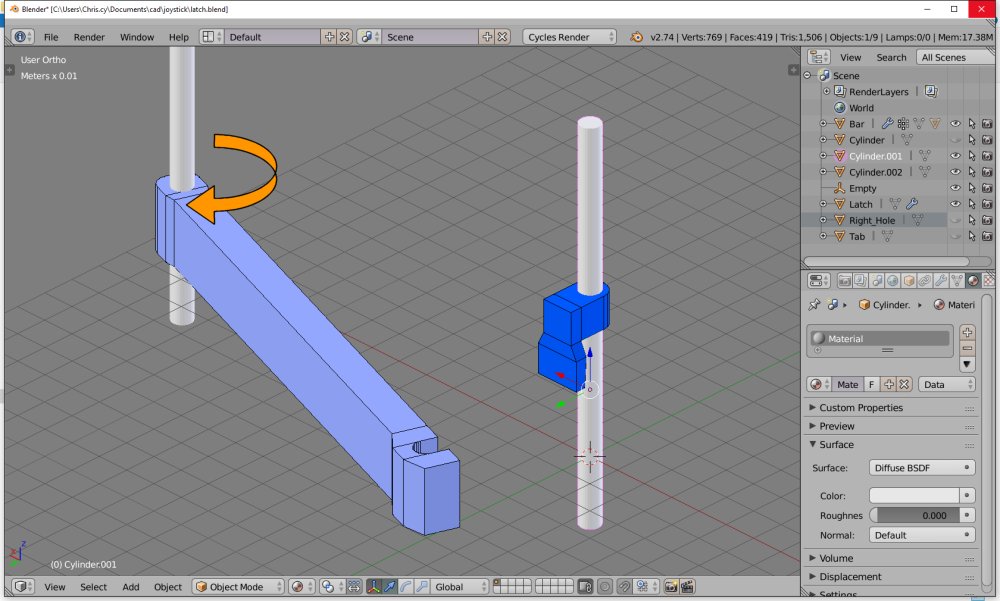

To recap where we left off, the wheelchair is stuck in the state where only the attendant controls will work. Also I cannot get it into programming mode to undo whatever I did wrong. Meanwhile I’m redesigning the joystick mount because the one that the vendor provided will not stay steady enough around my neck. I had already designed a swing away crossbar that would go across the front of the U-shaped rod that hangs around my neck. Now I need to design something that will fastened to that and will hold the upright piece to which the joystick is mounted. I spent all day Sunday April 10th watching NASCAR and designing and printing parts.

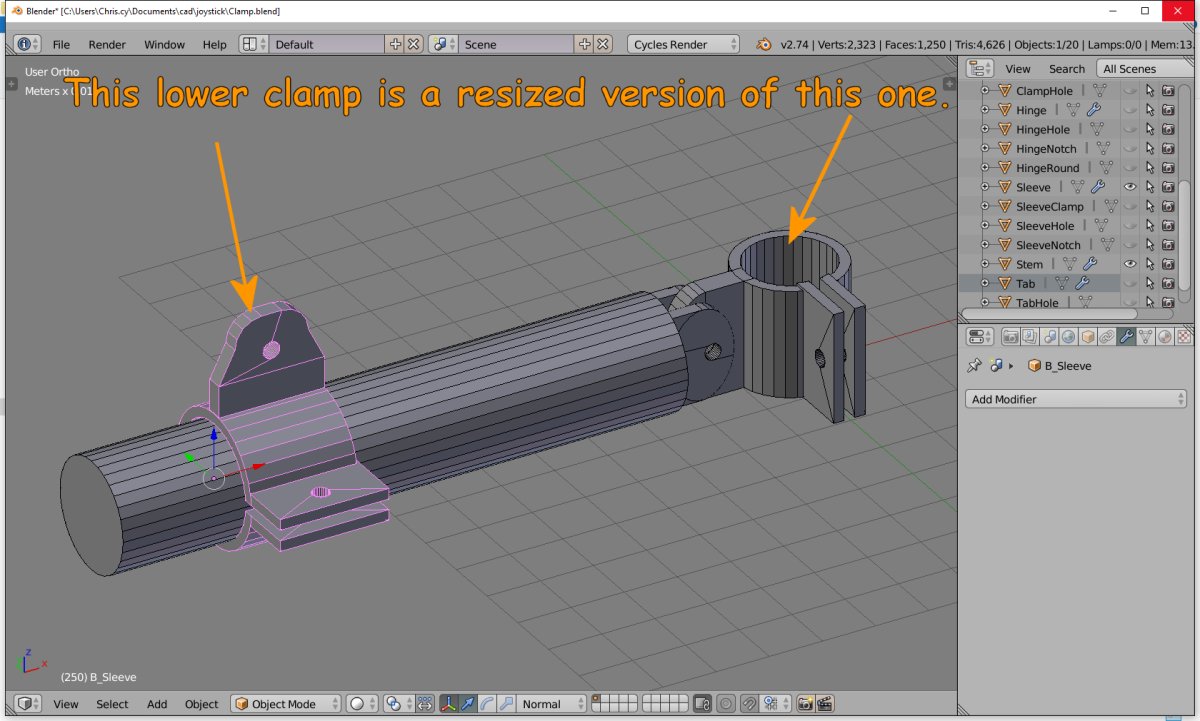

In the image below the long cylindrical piece and clamp on the right were pieces I had already designed. The clamp on the right holds the actual joystick. The piece I worked on Sunday was the clamp on the left which will attach the entire assembly to the crossbar. It turned out I could just copy the clamp on the right and resize it. As always you can click any of the images here to see a larger version.

On Monday April 11 we were supposed to take the wheelchair into the shop to have them reprogram it. Unfortunately my caregiver had to cancel and dad had to get me dressed. She has had a lot of things going on in her life lately. She has a young daughter with recurring ear infections, the transmission went out on her car so she has to borrow a friend’s car or get a friend to actually drive her to my house. She had been working for me for about three weeks and still had not worked the entire week without missing at least one day. She does absolutely wonderful job when she’s here. Fortunately she seems to have since gotten things worked out and has not missed a day since then.

I had had second thoughts about taking the wheelchair in for repair in the first place. I kind of wanted to be there while they were working on it so I decided to not take it in but to have them come to me. They had told me they can send someone on Thursday the 13th. I had tried to get them to hold that appointment for me in case I couldn’t make it on Monday because I knew my caregiver girl was a little bit unreliable lately. They had said I could just call and reschedule. They would not hold the date for me. When I called them back they said the Thursday appointment had been filled. The soonest they can get here would be Monday the 18th. Like I said… S.S.D.W. I spent the rest of Monday working on an installment of this blog.

All Printed up and Nowhere to Go

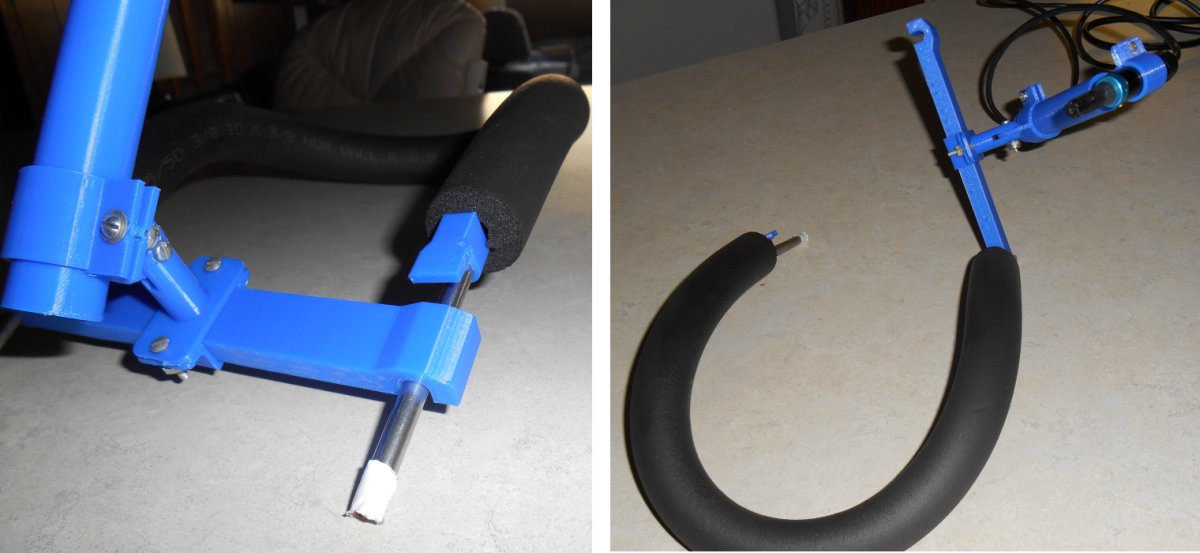

On Tuesday I finally finished all of my 3-D printing parts and we assembled the joystick mount. Here are some photos of the completed project.

This shows the latching mechanism and how it swings open so that you can fit the device around my neck.

Here’s what the device looks like when I wear it. Note in the background the calendar behind my head and it looks like Michonne from The Walking Dead is trying to chop off the top of my head.

The only problem I have now was the wheelchair would only work using the attendant controls because the software was glitched. I was all dressed up… or rather all 3-D printed up… and nowhere to go.

Also on Tuesday I had my monthly visit from the nurse from my home health agency. They send someone out once a month just to take my blood pressure, temperature, and see how things are doing in general. Also on the same day by coincidence I had my quarterly visit from my caseworker from CICOA (Central Indiana Council On Aging). She helps me wade through all of my Medicaid issues and she does my case management to get Medicaid to pay for the home health aide. I was able to show them the new wheelchair but I couldn’t really show off driving it which was a disappointment. I spent the rest of the day doing some Internet research to try to better understand what might be going wrong with the programming and other issues.

Going on Tilt

When playing poker and you get a bad beat, it rattles you emotionally and sometimes you start playing badly. In poker parlance this is called being “on tilt”. With all the ups and downs I’ve had in trying to get the wheelchair to work right I felt like I was permanently “on tilt”. Alternative title for this section could’ve been “Tilting at Windmills” considering we seem to be on a hopeless quixotic quest and getting a working wheelchair was an “impossible dream”.

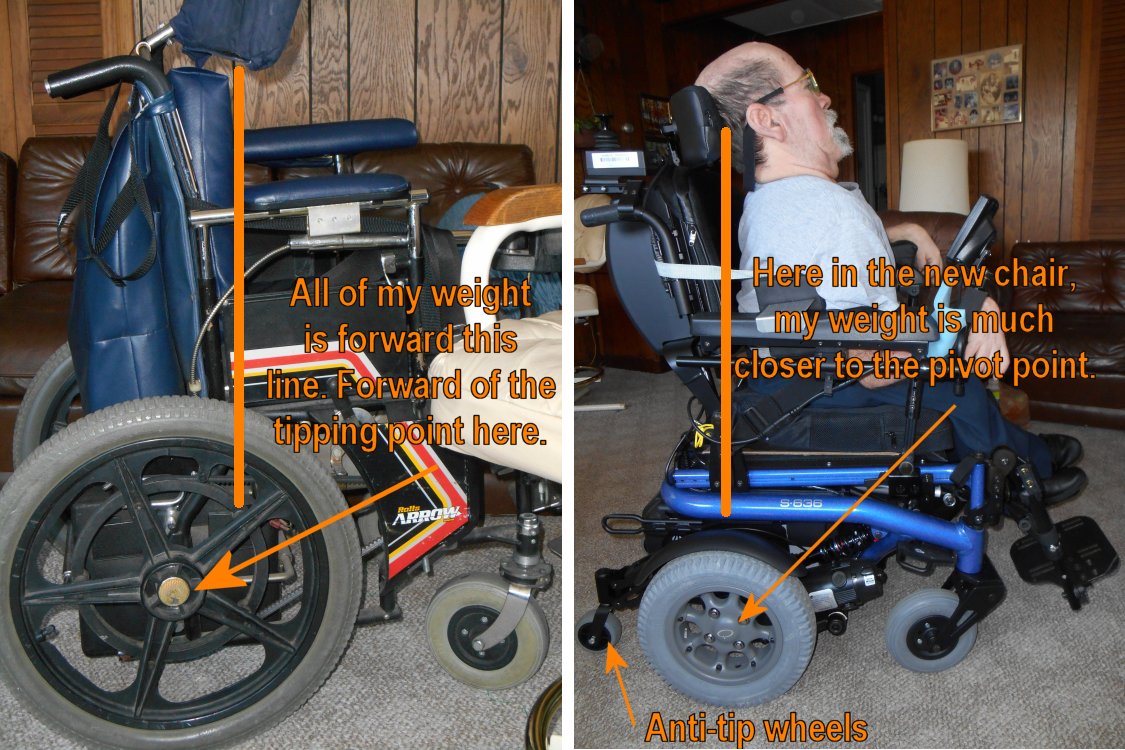

Clever clichés aside, the next topic actually did have to do with tilting. Most wheelchairs have some sort of little “wheelie bar” out the back of the chair to keep it from tipping over backwards. My old chair had a bar on each side with a tiny wheel perhaps the size of a skateboard wheel. The bars were easily removable and that was one of the first things that I did when I got the old chair. By removing them, it is possible to have someone tilt my chair backwards to go up a small step or a curb.

Only twice in my life do I ever recall coming close to tipping over backwards in the chair. There was one particular ramp at Market Square Arena that was way steeper than the others. Trying to go up it one time I was a little bit worried the front end of my chair was getting a little bit light. There was another time my mom was driving me up a small wooden ramp up a step at a retreat center in Culver Indiana. Halfway up the ramp she accidentally jerked the joystick a tiny bit and my front wheels raised. Fortunately she stopped quickly before I tipped over backwards. The only time I actually tipped over backwards was the day that my van lift fell and I tipped over and landed on top of my friend Judy. That’s a story for another day.

I do know that even on level ground it is technically possible to get my old wheelchair to tip over. You would have to put it in high-speed, drive it backwards at full speed, and then slam it into forward at full speed. You could get it to tip backwards that way. But even when I had much better use of my hands, I was never driving it that way to begin with. Once my arms started giving out it was physically impossible for me to make such an abrupt maneuver.

A popular design for new wheelchairs these days is what they call “mid wheel drive”. The chair essentially has drive wheels that are fat tires perhaps 10 or 12 inches in diameter in the middle of the chair and then it has caster wheels in both the front and the rear. The photo on the right is a Quickie Series 7 chair (mine is a 6). Essentially the chair has six wheels. It has a strange suspension system that keeps all six wheels on the ground as you go over rough terrain. And if you have a rounded curb or an obstacle like a speedbump it will climb up or down that very easily. But to go up a square step have someone attempt to tip your wheelchair backwards for you, there’s no way to do it. That’s why I didn’t get the Series 7 and got the rearwheel drive Series 6.

A popular design for new wheelchairs these days is what they call “mid wheel drive”. The chair essentially has drive wheels that are fat tires perhaps 10 or 12 inches in diameter in the middle of the chair and then it has caster wheels in both the front and the rear. The photo on the right is a Quickie Series 7 chair (mine is a 6). Essentially the chair has six wheels. It has a strange suspension system that keeps all six wheels on the ground as you go over rough terrain. And if you have a rounded curb or an obstacle like a speedbump it will climb up or down that very easily. But to go up a square step have someone attempt to tip your wheelchair backwards for you, there’s no way to do it. That’s why I didn’t get the Series 7 and got the rearwheel drive Series 6.

Although my new chair has rear wheels behind the drive wheels, they normally sit about a half inch off the ground. They are only to be used as an anti-tip mechanism. They have a strange retraction mechanism that appears to be spring-loaded. There is a cable running from each of the rear wheel assemblies to some sort of motor or actuator in the front of the chair underneath the seat. When we had the demo chair we couldn’t figure out how it worked but we figured we would be removing these anti-tip wheels anyway. Sadly the wheelchair salesman wasn’t sure how they worked either.

We did have some concern that if I was reclined, the chair I buy back might be at risk of tipping over backwards and we might need to keep them in place. We were going to have to do some experimenting before we actually removed them. As you can see in the side-by-side images below, the center of the rear wheels of my old chair were probably six or 8 inches backwards from the position of my back. But in the new chair because the wheels are smaller diameter and the way it is constructed, the center of the rear wheels is almost directly below the point where my back hits. While this new chair is heavier and the weight of the equipment is further forward under the seat than my old chair, the actual tipping point is a little more dangerous.

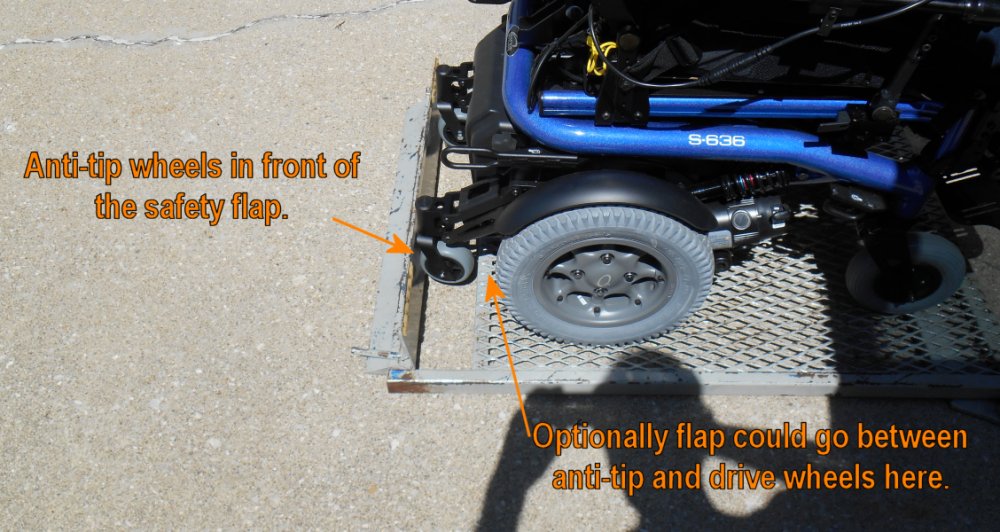

The other issue that concerns us about these rear wheels is that the chair might not fit on the wheelchair lift on my van. When we had the demo chair, I did not ride it on to my wheelchair lift but dad did try rolling it up on the lift without me. He thought that the chair would not fit with those anti-tip wheels sticking out the back. There is a metal flap that folds up behind the rear wheels to keep me from rolling off. Dad thought that the only way to get that chair to fit would be to put the flap in the space between the anti-tip wheels and the drive wheels. That would definitely be awkward and yet another reason why to remove these unnecessary wheels. The photo below shows my wheelchair sitting on the lift platform with the anti-tip wheels in front of the flap. It turned out that when we actually put me on the lift with me sitting in the chair and did some experimenting that I would fit with the anti-tip wheels in front of the flap. Unfortunately to get into that position we had to roll me so far forward that my feet would hit the bumper of the car. I actually had to slide my feet backwards on the foot rests. When sitting in my old chair I was that lower and thus my foot rest was lower and my feet would fit under the bumper when I rolled forward. Anyway even though I would fit on the lift, it was going to be a complicated process.

One of the things we couldn’t figure out was why there was such a complicated mechanism on these wheels. It looks as though there some sort of spring-loaded suspension system and then there was this cable that runs to the front of the chair and some sort of actuator. But we couldn’t figure out what activated it. We couldn’t find anything of the user manual that explained it in the dealer had not been able to explain it.

>So I got online to my new favorite go to place for all things wheelchairs, an online discussion forum at wheelchairdriver.com. I asked them if they thought it was safe to remove these wheels and what was the complicated mechanism all about. You can click here to read the thread but the gist of it is that they didn’t think I should remove them. Of course these are people who are a lot more active than I am riding their chairs around on rough ground. If I have this chair when I was in my teens it was a bit of a different story. It was also interesting that the members of the forum got into a heated debate on whether or not the Quickie Series 6 was actually “rearwheel drive”. One guy said it’s a compromise between a mid wheel and a rearwheel with all of the disadvantages of both. I guess he wasn’t a fan.

>So I got online to my new favorite go to place for all things wheelchairs, an online discussion forum at wheelchairdriver.com. I asked them if they thought it was safe to remove these wheels and what was the complicated mechanism all about. You can click here to read the thread but the gist of it is that they didn’t think I should remove them. Of course these are people who are a lot more active than I am riding their chairs around on rough ground. If I have this chair when I was in my teens it was a bit of a different story. It was also interesting that the members of the forum got into a heated debate on whether or not the Quickie Series 6 was actually “rearwheel drive”. One guy said it’s a compromise between a mid wheel and a rearwheel with all of the disadvantages of both. I guess he wasn’t a fan.

The bottom line is that these wheels are supposed to be able to flex upwards so that you can go up and down curbs and ramps. However if you recline the wheelchair, that mechanism gets locked in the down position keep you from tipping while reclined. Some people said that their anti-tip wheels were constantly touching the ground while most people said that like mine they were slightly off the ground. One guy said that his dealer made a modification with a wedge-shaped part that would adjust the height of the down position. A few days later going through some paperwork we found an addendum that explained this little extra block could be inserted but it didn’t make it very clear what that little block would do for you.

Need Knowledge… Do an Experiment

When the experts can’t agree and the instruction manual doesn’t instruct there’s only one thing to do… actually experiment. Over Wednesday and Thursday of that week we tried a number of different things. We got me on and off the van lift and I rode up and down and actually got in the van. More on that later. We drove me out to my front curb. Our curb is about 6 inches tall and is very rounded however when I was younger and rode around the neighborhood a lot I used to have trouble getting up and down it so dad poured a small concrete ramp in the center. We drove me down the ramp okay and then we tried driving up the rounded part of the curb. It had the power to get the front wheels climb up the slope but because the rear anti-tip wheels would not retract it was lifting the drive wheels off the ground. When we went back to drive up the ramp we almost couldn’t get me to go. The chair would roll down the ramp okay whether the drive wheels were touching or not. When we tried to drive up again, we realized that the drive wheels were barely coming off the ground. It was just enough to lose traction. We had to get a bit of a running start to get me up curb even with the ramp. We had hoped that once the full weight of the chair was on the anti-tip wheels that they would retract a tiny bit. Unfortunately they did not. Something weird was going on because they should retract as long as I wasn’t reclined any.

it was clearer than ever that the wheels were going to be in the way and severely limit my ability to go up and down even small ramps if they were sufficiently steep. We still didn’t know just how tippy this chair would be because anytime we tried to tip it, the wheels would hit. It wasn’t until the next day that I came up with another idea. We went back outside and parked the wheelchair on the front porch which is up about a 4 or 5 inch step from the driveway. We parked me with the anti-tip wheels hanging off of the edge of the porch into the driveway. This would allow dad to try to tip the wheelchair in a controlled manner. He tried tipping the chair back with me sitting at my normal seating position as if he were trying to take me up a curb. It seemed to him the chair was no more or less tippy than my old chair was.

Then we gave it a real test. We reclined and tilted the wheelchair all the way back and he tried to see if it would tip. He could put a lot of weight on the rear of the chair and make it tip but it didn’t seem like there was any way it was going to tip by itself. Keep in mind I would not be driving the chair anywhere or be driven anywhere while in that reclined position. I wouldn’t do it on uneven ground.

“Never Start 2 New Foods at Once”

The above quote is a proverb that my mom always used. She always said that when you are trying to get a baby to eat solid food or different kinds of baby food that you should only try one thing at a time. If you try 2 new foods at once and the baby has a bad reaction to it, you don’t know which one was responsible. It’s been a philosophy that has served me well in dozens of situations whether it was building gadgets or troubleshooting software. If you make 2 changes at once and something goes wrong then you are clueless. So even though we had come to the conclusion that it was safe to remove the rear wheels, we were not going to do it right away. I was concerned that messing with it might trigger some sort of safety mechanism and shut the chair down completely. We had already gotten in trouble when I messed with the programming. I wanted to wait until we solved the programming problems before we made any new changes to the chair. Unfortunately a few days later we did not heed the “2 new foods” rule and it got us into more trouble. But that’s another story.

More Comfort Issues

Other activities of this week included padding and reupholstering the armrests. The armrests that came with the chair were very hard rubber with little or no cushioning in them. They also had a concave shape on the top surface which would be great to keep your arm in place if you lay your arm absolutely parallel with the length of the armrests. However I like to keep my arm sometimes at somewhat of an angle and so the edges of the concave shape dig into your arms. I had been referring to them as “an armrest only a quadriplegic could love”. We had been putting a pillow under my arm but then as an experiment we cut a piece of foam and put it on the armrest with duct tape. After a few days I decided that was the right height for a permanent solution. Dad went out to the fabric store in Avon and purchased a few square yards of dark blue Naugahyde upholstery material and made covers for the foam.

We also came up with a temporary solution for had to mount my ultimate remote control and my iPhone. I used to have a gadget that was an aluminum bar that would fastened to the upright portion of my armrest. We had two of them in fact. One of them held an easel on which I can put books or papers. I would use it if I was giving a speech somewhere and didn’t have a table in front of me. I had used it at Enneagram seminars and some RCIA classes. I also had a similar manner for my video camera when I used to hang out at the Speedway and shoot video in the garage area. I no longer had used for either of these so we repurposed the swingarm part of it by cutting a slot in the end that would hold my iPhone bracket from the other chair. The upright pipe on the armrest is a different diameter so dad had to do some cutting and grinding but we got it to work. The iPhone bracket itself will probably get redesigned into a simpler form that will probably hold the iPhone a tiny bit higher but for now it’s good enough. We are thinking about possibly moving the LCD display from the right arm rest of the wheelchair onto this adapted swingarm. The display currently is not in a very useful position and I can’t really see it where it’s at. Anyway it was great to be able to use my TV remote and my iPhone again.

After being so frustrated with the wheelchair, I needed to take a break so I took a day off from working on it to play with a raspberry pi. I mentioned in a previous post that I was replacing an old raspberry pi model 1 B with a newer model 2 and giving the old one to my friend Buz who lives in Michigan. Fortunately getting the old one running for him went much smoother than setting up the new one for me. After getting it ready here, I mailed it to him and the following week we got together on Skype and I talked him through how to set it up. It was a lot of fun connecting with an old friend. We will probably do more Skype in the near future.

Saturday I planned to go to church and as we had not yet gotten a hold down straps installed in the van I had to sit in the old wheelchair. I couldn’t believe how uncomfortable I was all day long. The new chair really had me spoiled.

On Sunday the 17th I spent the day watching NASCAR and IndyCar and working on the blog. Hopefully next week would be a both better week. The repair man was scheduled to come on Monday. That would also be my dad’s 81st birthday. Hopefully it would be a really good day.

There is one other incident during the week on Thursday April 14 that I need to blog about but it doesn’t really have anything to do with the wheelchair. It was something of a more personal nature which belongs on my personal blog rather than my technology blog (even though technology is very personal for me). You can read the story on my personal blog here. So that wraps up the third week after my new wheelchair arrived.

A Week of Frustration

In this installment we will cover the second week of working on the new wheelchair. We work on 3-D printing parts for the joystick and waiting on word from the wheelchair people about my programming glitch.

That’s Why They Call It Immediate Care

After taking off for the weekend and not working on the wheelchair I was anxious to get back to work on it first thing Monday April 4. I was also hopeful I would hear from my wheelchair technician about my technical problems. Unfortunately my body had different plans. I woke up about 3 AM Monday morning with a very nasty earache. While I had been eating my bedtime snack Sunday night consisting of chewy chocolate chip cookies and a bottle of chocolate Ensure, I think I swallowed funny and some of the liquid went up the tubes that connect the back of your throat to your inner ear. I normally have tinnitus which is a ringing in your ear and it is normally equal in both ears and at a level that doesn’t really bother me. But when I woke up my left ear was ringing very loudly and hurt terribly. It was like there was a lot of pressure built up. I tried swallowing and yawning to clear the pressure and it felt like the tube was clicking open but it also felt very irritated and it didn’t relieve the pressure. I called dad and had him roll me over in bed and took some liquid Tylenol. I told him that we would call the ear doctor first thing in the morning and try to get me an appointment. If I wasn’t successful I warned him I might have to go to the ER. It was definitely the worst earache I’d ever had.